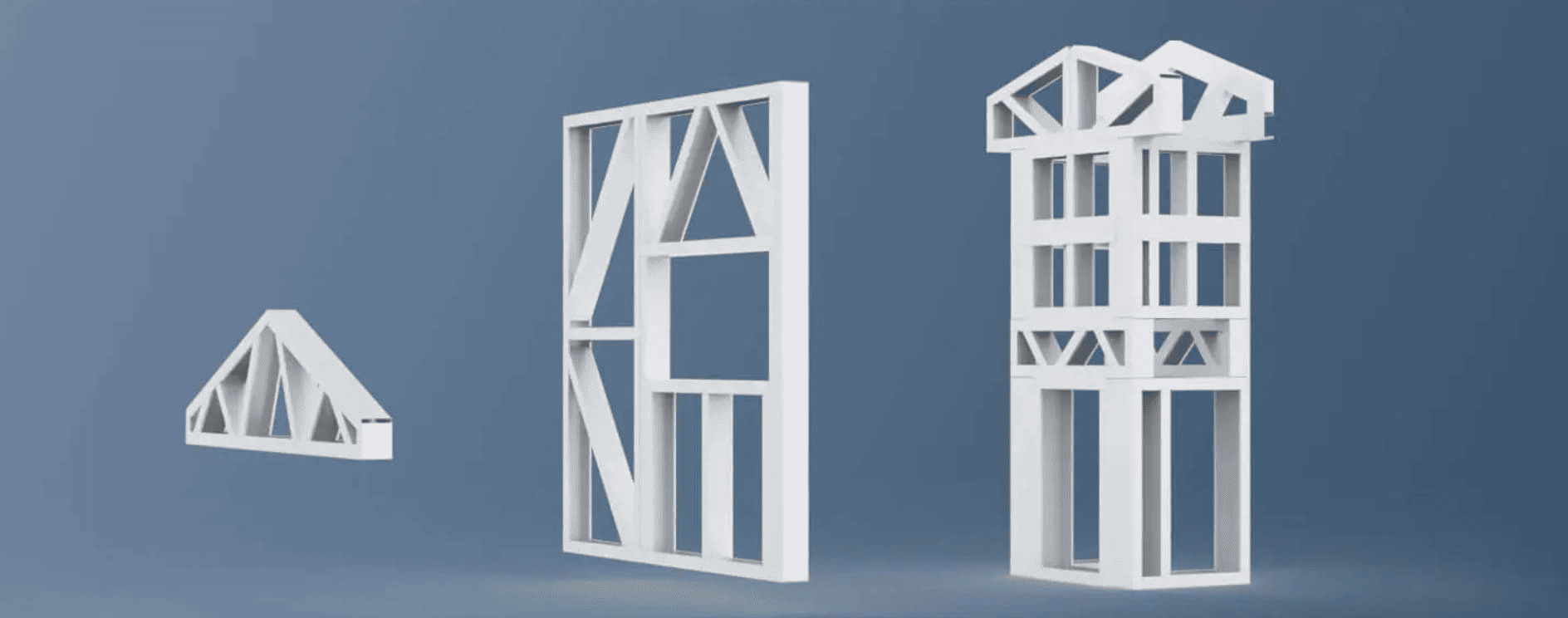

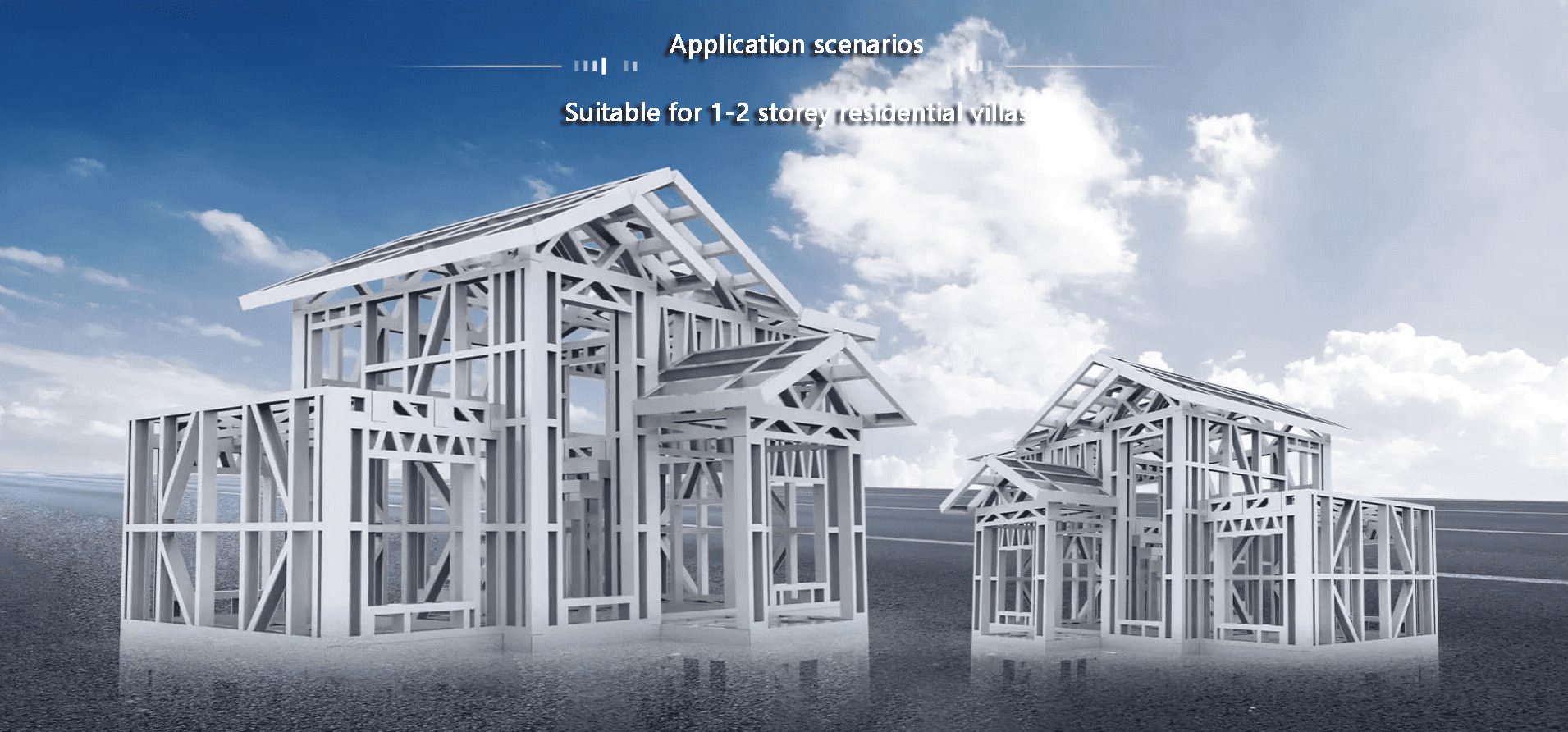

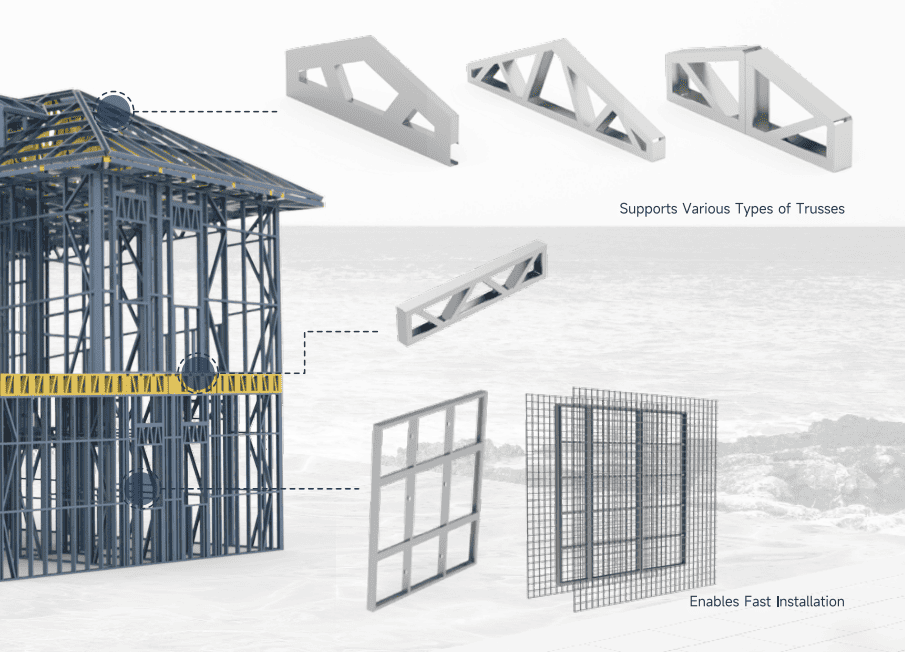

The LG2025 Light Gauge Steel Framing Machine is capable of producing C profiles with a bottom width of 89 mm. Equipped with an advanced servo motor and powered by software developed by Hiteknova, it supports the precise CNC machining of multi profile components. During operation, design data can be directly imported, or customized parameters entered to produce light gauge steel with various hole patterns in a single specification. It is suitable for wall panel frames, roof truss frames, and floor joist frames in 1-3 stories commercial buildings and low-rise residential structures. It reduces material waste and incorporates dual-power traction to ensure uninterrupted operation, thus enhancing production efficiency.

Step 1. Vertex BD Design Software Construction design through Vertex BD design software, design data NC output to production software

Step 2. HBS LGS Production System Input design data from Vertex BD NC output. Self-develop HBS LGS Production system Controls the production equipment and refine the frame structure Vertex BD software Design

Step 3. HBS Machine The PLC panel is able to make clear to each component production current process. It can timely reproduce any failed products resulted from any reasons in the production process

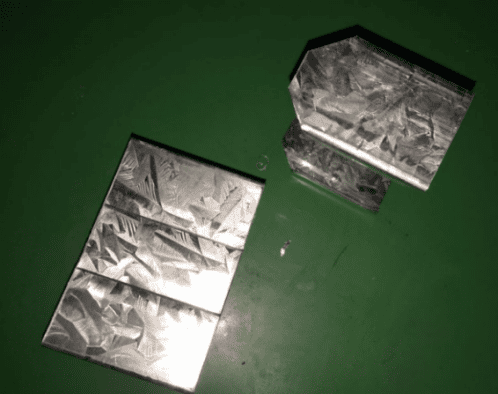

Step 4. Assembly Different components have independent inkjet coding. Assembly as per the drawing from Vertex BD software. LGS Production System with Two Features: Feature 1. Material Saving: With the output code of Vertex software, there is always an inevitable material waste of 45-50mm when it comes to one part with chamfer cut or with flat cut, such wastage can amazingly reach 1.7-2.1%. Based on above calculation, a yearly production of 5000 Tonapproximate will generate 100 tons wastes. However, in view of this situation, HBS LGS production system has made a serials optimization, which minimizes the wastage to a minimum.

(See below photos for reference)

HBS Equipment controlled the waste to a minimum

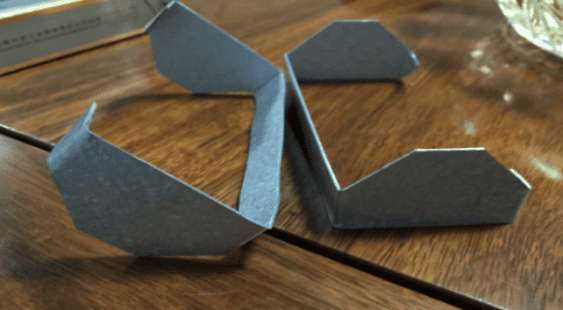

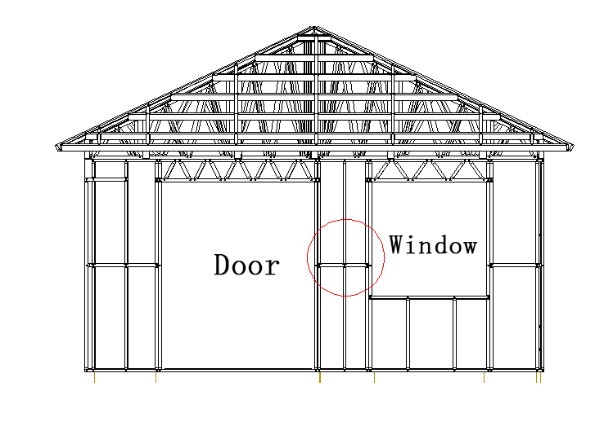

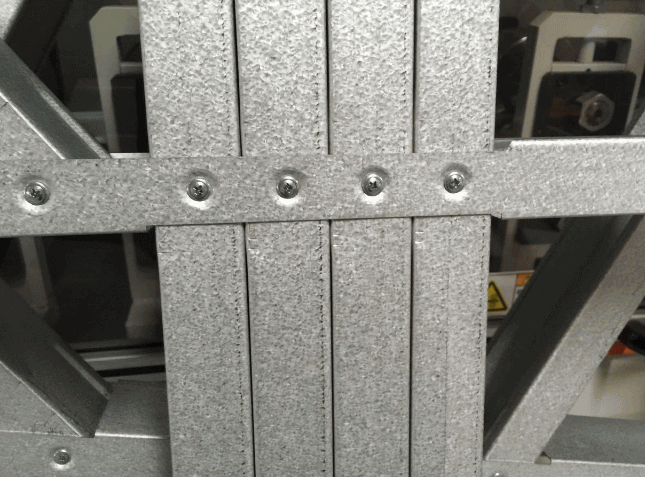

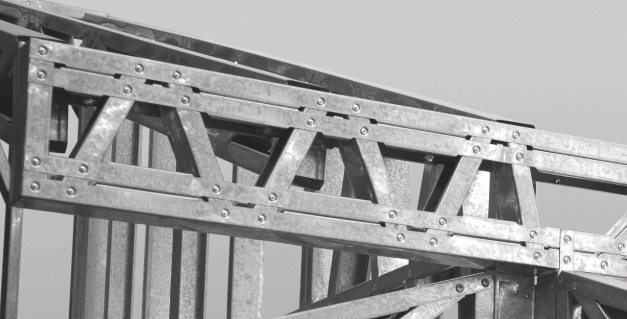

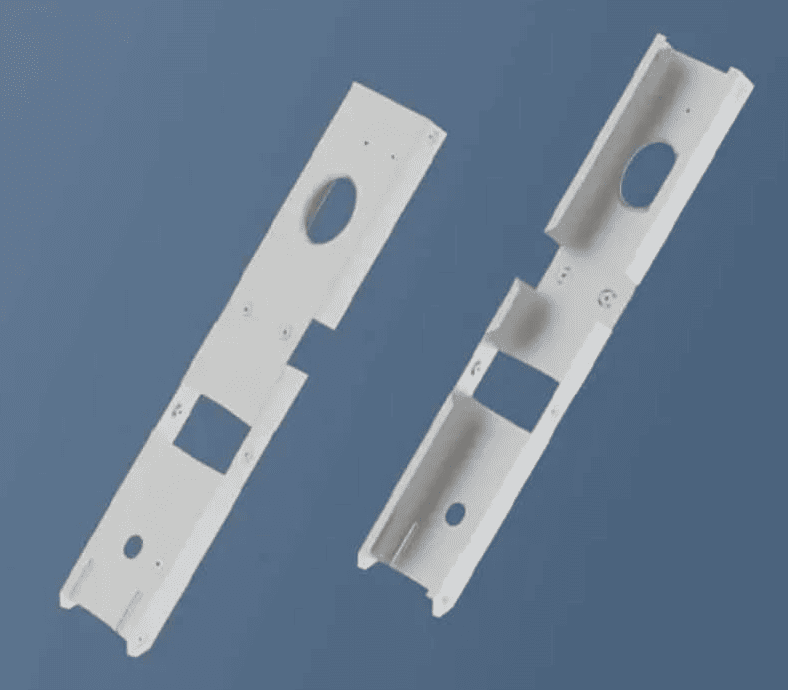

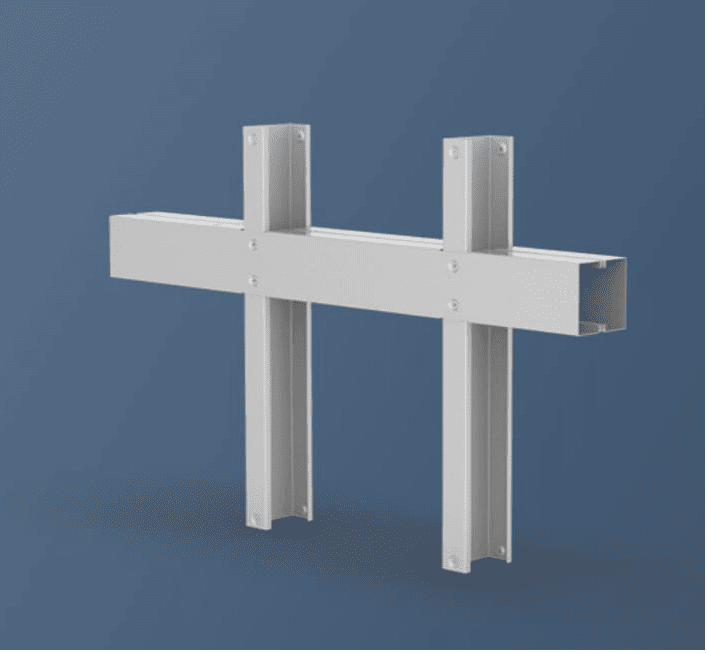

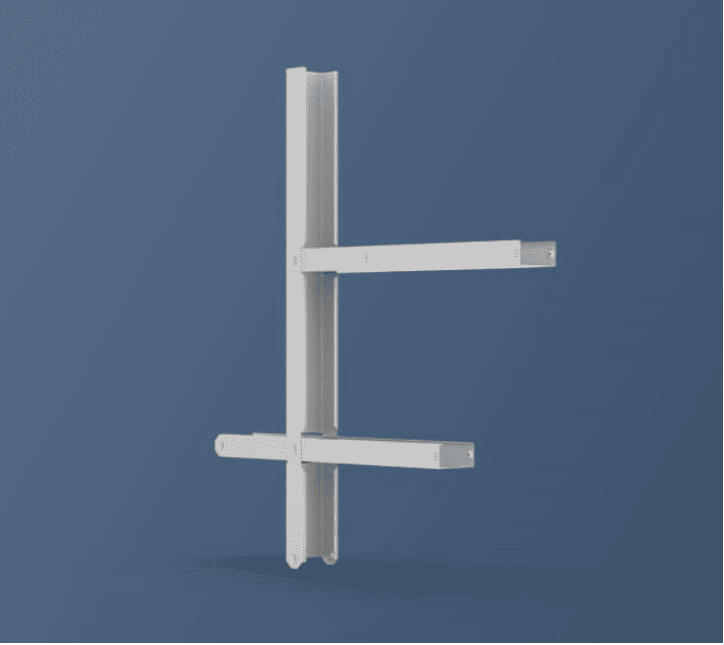

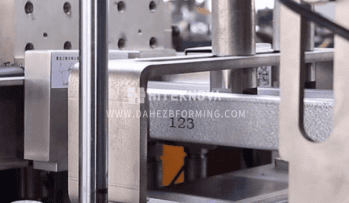

Feature 2. No Jammedon Machine: In many cases, when it comes to large door and windows(pic.1 red circle part), there is a special design on the header, Crip stud or Jack stud. To ensure the structure intensity, the designer would normally design the column parts into groups like pic.2. Such structure component parts are rather easy to jam the machine. It might take at least 1 hours to debug machine with askillful operator. The roller space has to be readjusted after the debug, otherwise it may bring severe damage like Shafter breaking, Roller crushing etc. Sheet are wasted again during the machine readjusting. HBShas invested capital & resource in improving LGS equipment especially on the roll forming station & Shearing station, to make sure machine won’t get jammed while producing special columns.

Pic1 Pic2

Column parts into group design examples

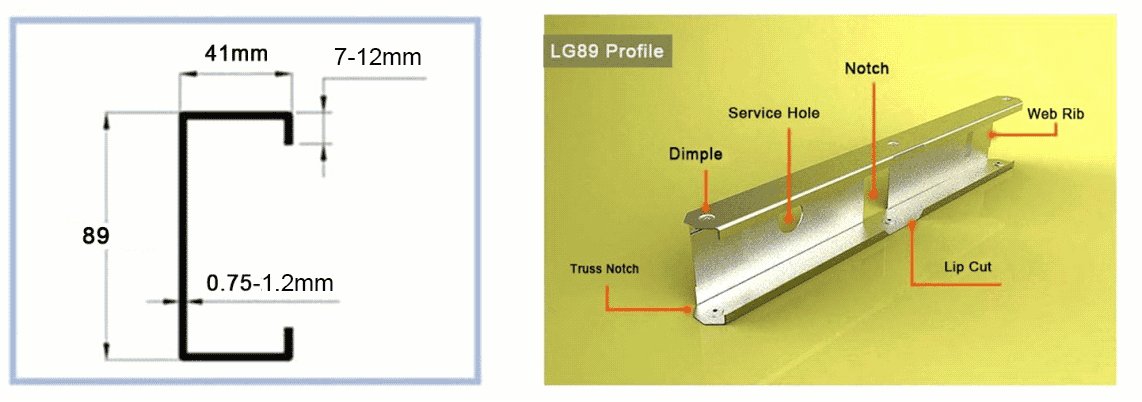

Specifications

- Material: Galvanized coil, Aluminum-zinc coil

- Thickness: 0.75-1.2mm(0.029’’-0.047’’)

- Width:89mm(3.5”)

- Flange:41mm(1.625”)

- Lip:7-12mm(0.30”-0.47”)

Technology Parameters

| Machine Weight | About 3.8T |

| Profile Shape | C |

| Dimension of forming parts | (length)5.5m x (width)1.25m x (height)1.65m |

| Section steel material | Q235,Q345,G550,Hot-tied galvanized strip steel |

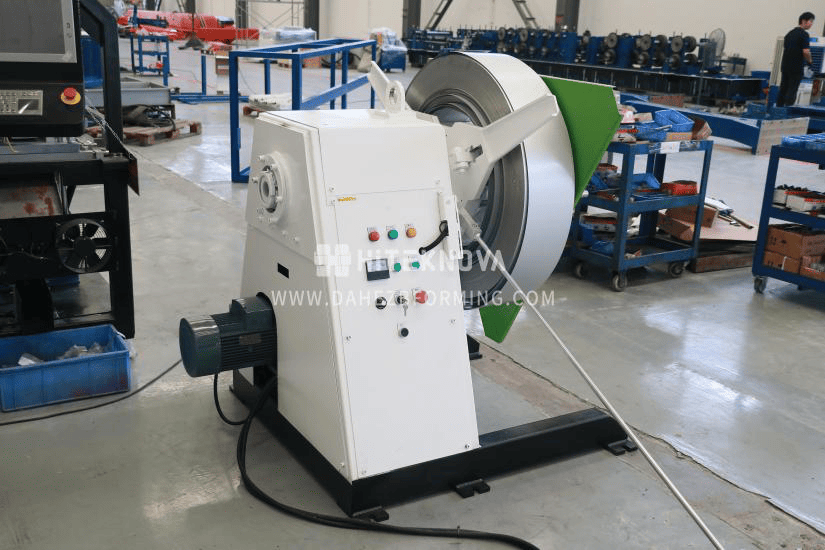

| De-coiler | Manual automatic de-coiler(FD20) (baffle) |

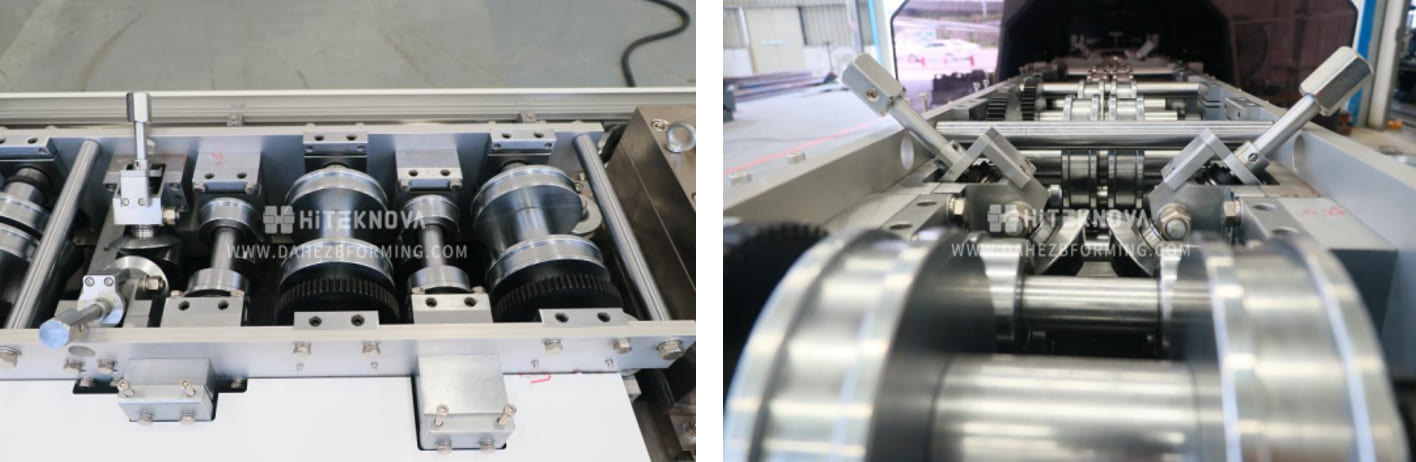

| Feeding | Upper and lower rollers + two sets of rollers |

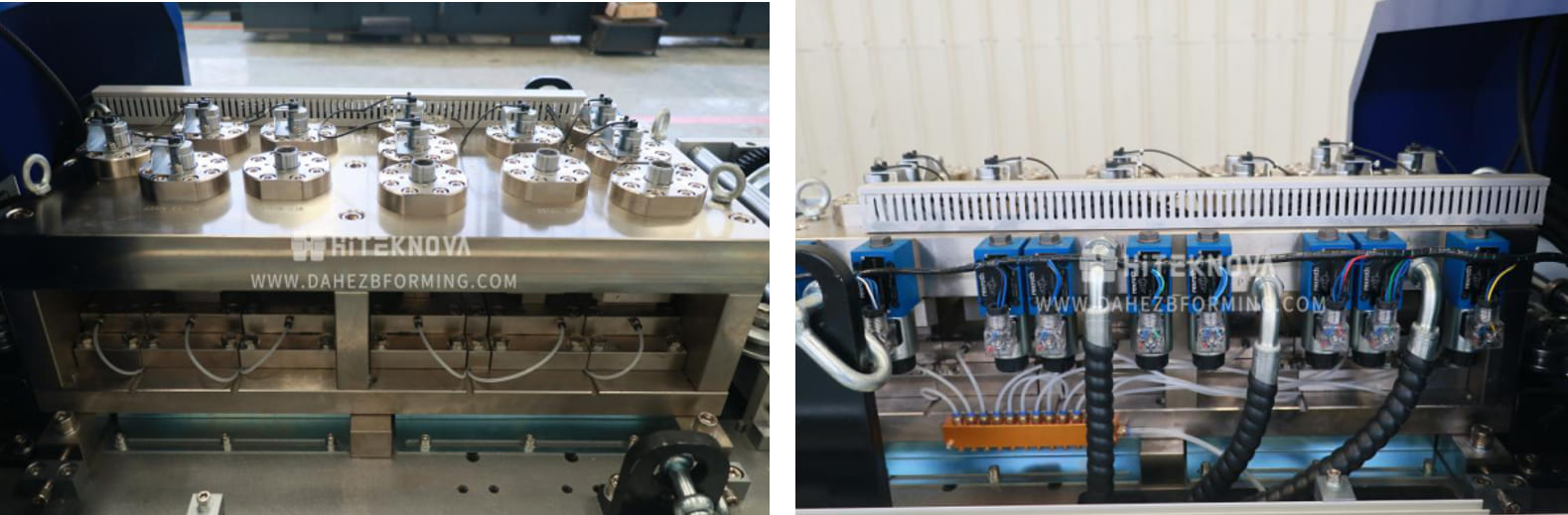

| Punching type | hydraulic punching |

| Hole Type | According to the pattern drawing |

| Main control cabinet | inch touch screen + 1 electrical main control cabinet |

| External controller | 1 |

| Drive | Servo motor (7.5KW) + precision planetary gear reducer |

| Main hydraulic station | Hydraulic station power 7.5KW |

| Out-let Table | 4m |

| Voltage | 380V, 50Hz, 3 Phase |

| Inkjet printing | Online inkjet printing system |

| Free Spare Parts | Easy wear parts |

| Specification book | 1 |

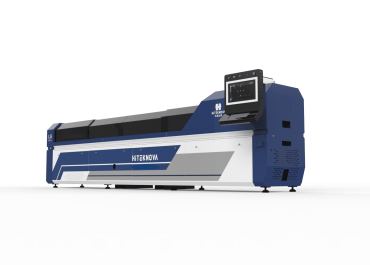

| Machine color | Ivory white + dark blue |

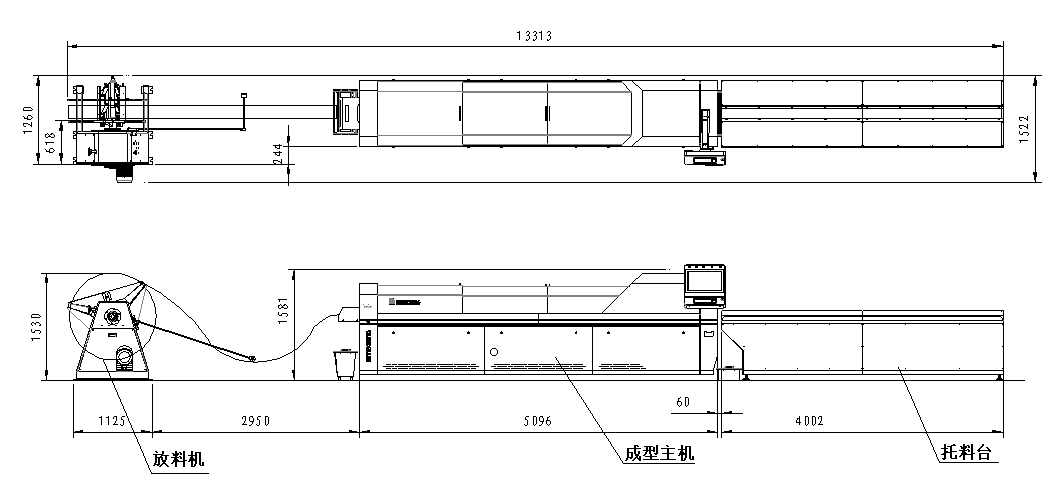

Production flow

De-coiler→ Leveling Device→ Punching Device→ Roll Forming System →Cutting Device →Out-let table

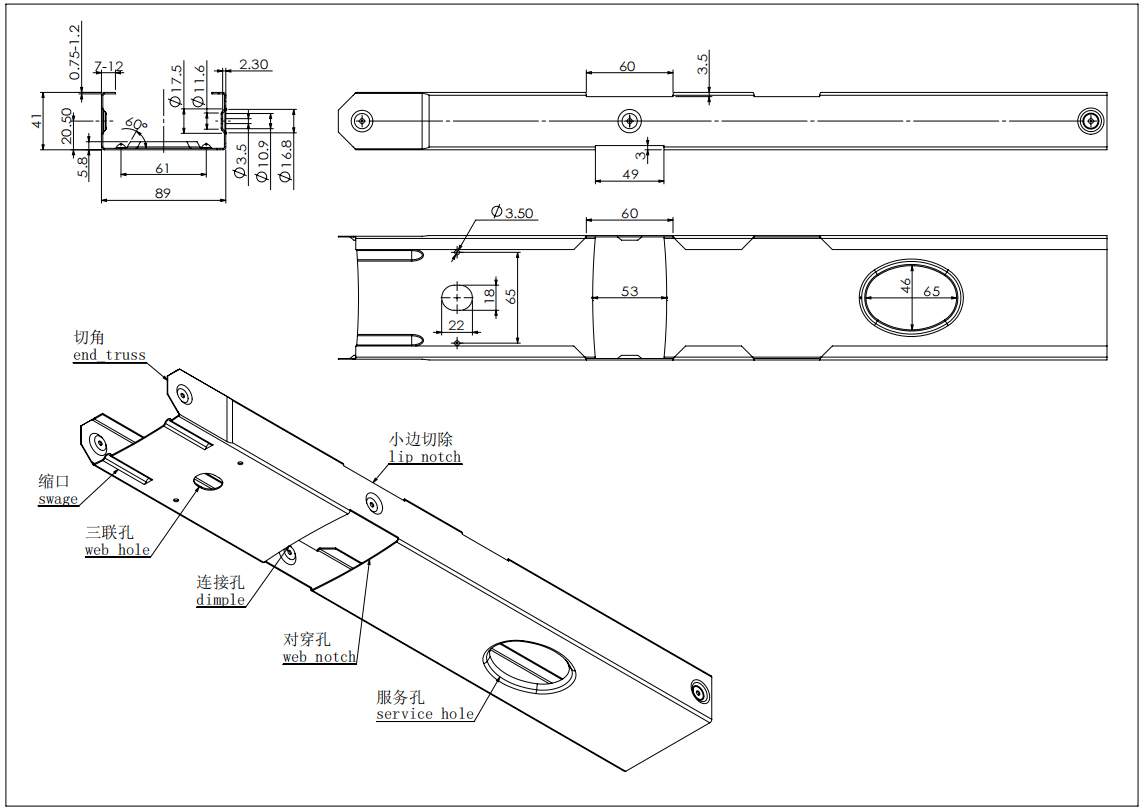

Profile Drawings

| Standard Metric Sizes | |

| Web Width | 89mm |

| Flange Height | 41mm |

| Lip Width | 7-12mm |

| Max Material Thickness | 0.75-1.20mm(22 gauge to 18 gauge),G550 Galvanized Strip Steel |

| Lip Cut | 60mm |

| Web Hole | 22x18mm |

| Dimple | 2.3mm x Φ16.8mm x Φ10.9mm x Φ3.5mm |

| Web Notch | 49x53mm |

| Service Hole | 46x65mm |

| Standard Imperial Sizes | |

| Web Width | 3.5” |

| Flange Height | 1.625” |

| Lip Width | 0.30”-0.47” |

| Max Material Thickness | 0.029’’-0.047’’(22 gauge to 18 gauge),G550 Galvanized Strip Steel |

| Lip Cut | 2.36’’ |

| Web Hole | 0.86’’x 0.7’’ |

| Dimple | 0.09’’x Φ0.66 ‘’x Φ0.42’’ x Φ0.13’’ |

| Web Notch | 1.92’’x 2.08’’ |

| Service Hole | 1.81’’x 2.55’’ |

- Custom Service Holes size available on request

- Custom Bolt Hole sizes available on request

- Custom Web Holes size available on request

- Punching precision within +/-0.5mm(0.02”)

- Speed of forming: High speed 48m/min, the actual production speed depends on the number of punched holes. (If there are special needs in terms of speed, you can communicate separately)

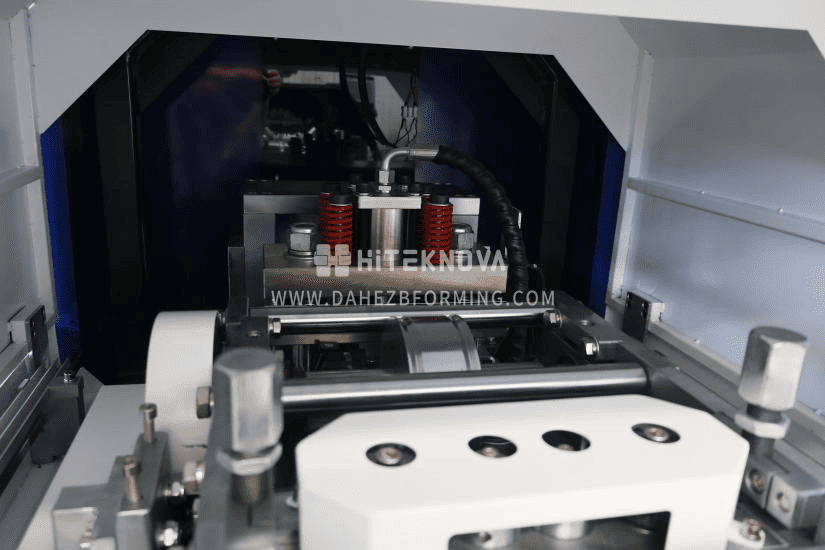

Machine detail

- De-coiler:Manual automatic de-coiler(FD20) (baffle)

2.Punching Device:Punching precision within +/-0.5mm(0.02”)

3. Speed of forming: High speed 48m/min, the actual production speed depends on the number of punched holes. (If there are special needs in terms of speed, you can communicate separately)

4. Hydraulic Cutting Device: Hydraulic Pressure 16Mpa

5. Out-let Table:The length of product support frame 4m

6. Main control cabinet: 21 inch touch screen (installed on the discharge end of the equipment) + 1 electrical main control cabinet (installed on the side of the equipment)

7. Online inkjet printing system:Marks and Item Number are available to be printed on the flange of both side for easy assembling pieces to pieces.

Application