Introduction

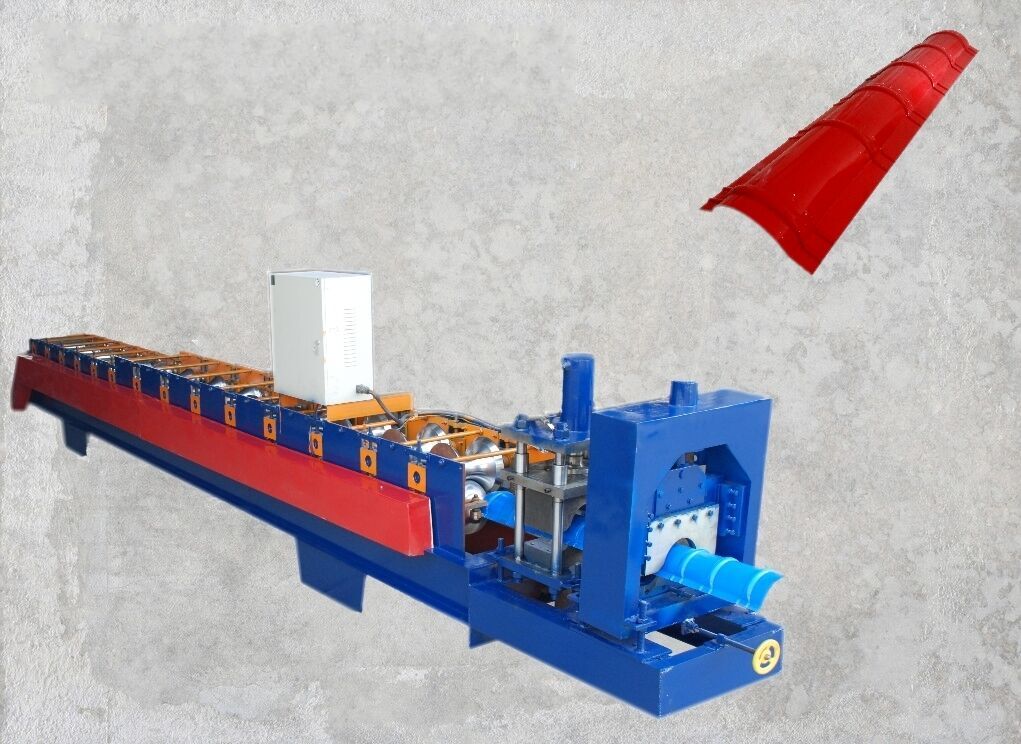

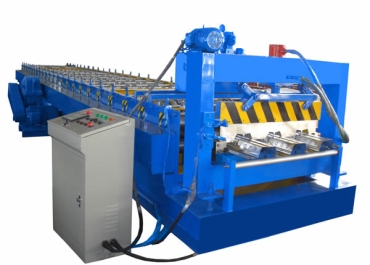

Colored steel tile forming machine consists of the following : uncoiler and its base, coil sheet guiding equipment, film covered device, roll forming system, pressing equipment, post-cutting equipment, hydraulic station, controlling system, supporter table

Machine Features

1. Precise forming.

2. High-solid forming stand guarantees the good and uniform quality of final products

3. The operation automatically minimizes the tolerance of cutting length.

Products Feature

1. A stylish and attractive design,giving the apperance of a traditional roof tile.

2. Resistant to frost,heat,hail and gales : 100% waterproof, thanks to the lateral run-off channel on each sheet for several models.

3. The raw material can be in different color, elegant and noble looking. It is widely used as the garden like factory, hotel, exhibition, villa, civil construction etc.

Precautions

1.Hydraulic Decoiler with Break is equipped for roll forming production, not manual one.

2.Refine steel plates in 22 – 25 mm as Sidewall of machine is used.

3.12 – 16 Nos of Rollers is used for ridge cap forming, ensuring profile strength.

4.Step forming by AC Motor is adopted for its ridge stepping.

5.Mitsubishi (Japan) PLC and 5.7′ Touchable Screen are used for for data processing and setting.

6.Roll forming speed is 2 – 12 meters / minute.

| NO. | Item | Parameter | Remark | |

| 1 | Suitable material | Type | Pre-painted sheet | |

| Thickness(mm) | 0.35-0.7 | Design based on 0.5 | ||

| Yield stress (Mpa) | 235 | |||

| Width (mm) | 340 | |||

| 2 | Forming speed (m/min) | 5M/min | Not including cutting time | |

| 3 | Main machine motor(KW) | 3×2 | Depend on final design | |

| 4 | Hydraulic station power(KW) | 5.5 | Depend on final design | |

| 5 | Total power(KW) | 11.5 | Depend on final design | |

| 6 | Power | AC380V,50Hz, 3Phase | According to customer request | |

| 7 | External dimensions(L×W×H, m) | 13×1.0×1.7 | Depend on final design | |