DETAILS

Hiteknova Q5 LGS System Advantage:

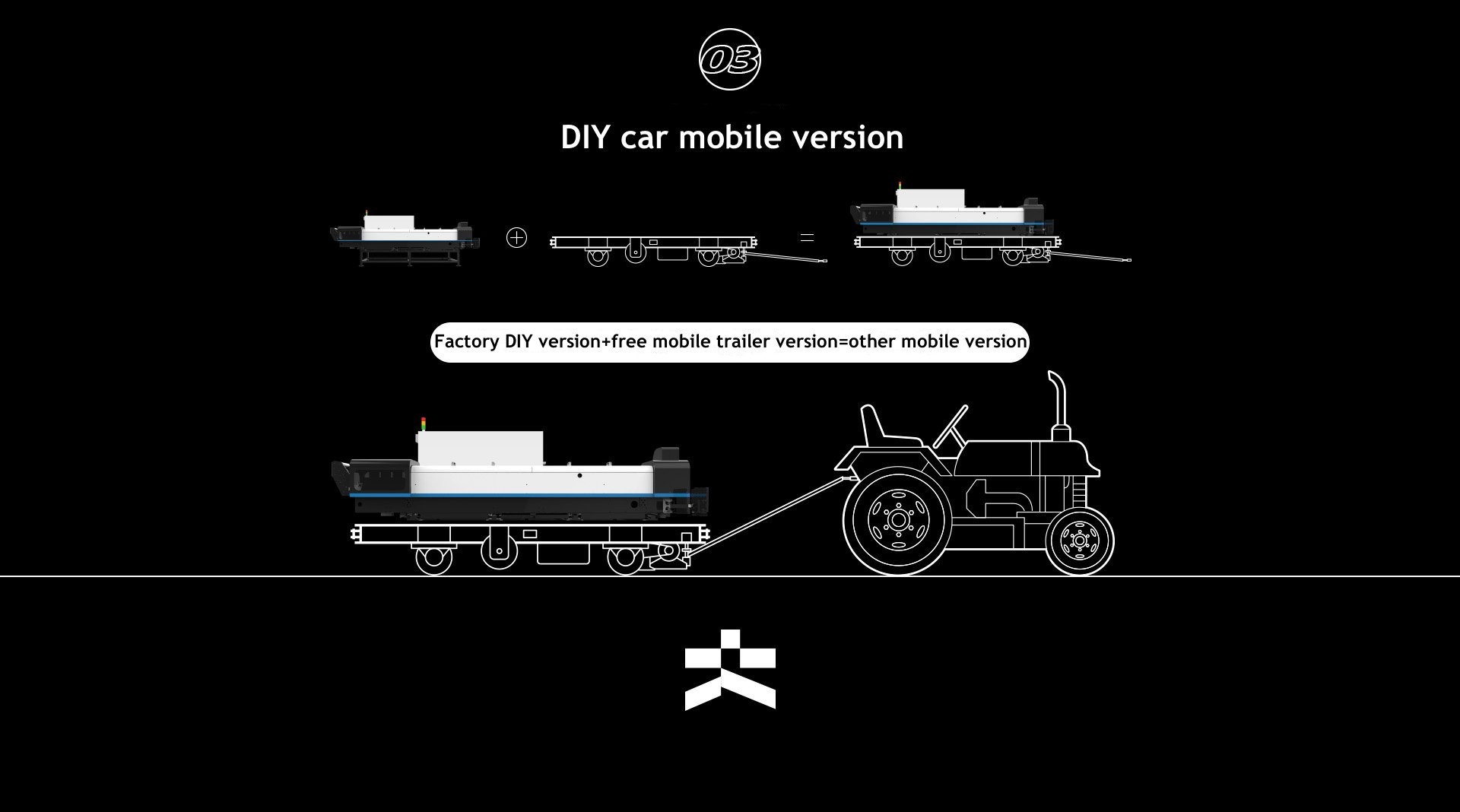

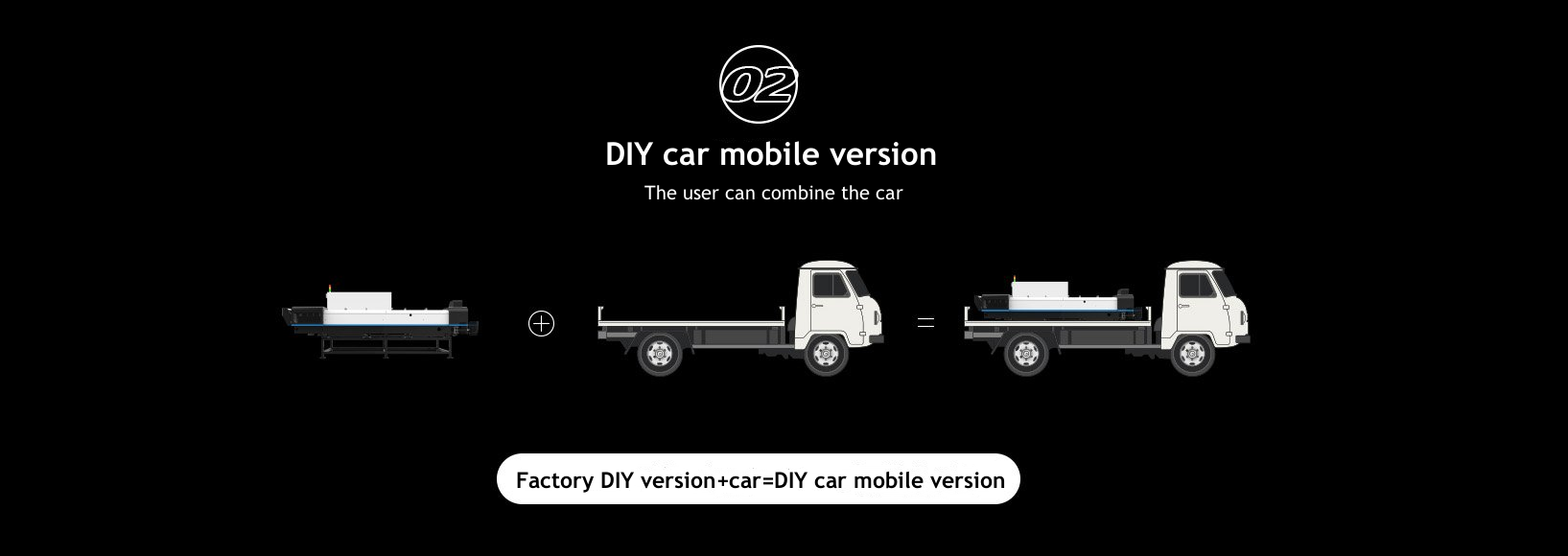

- Building nearby: Mobile intelligent building, where to drive, where to build.

- Short construction period: on-site processing and assem

- Low cost: low comprehensive cost, convenient construction

- Simple construction: fast assembly like building blocks, that is, safe and reliable production

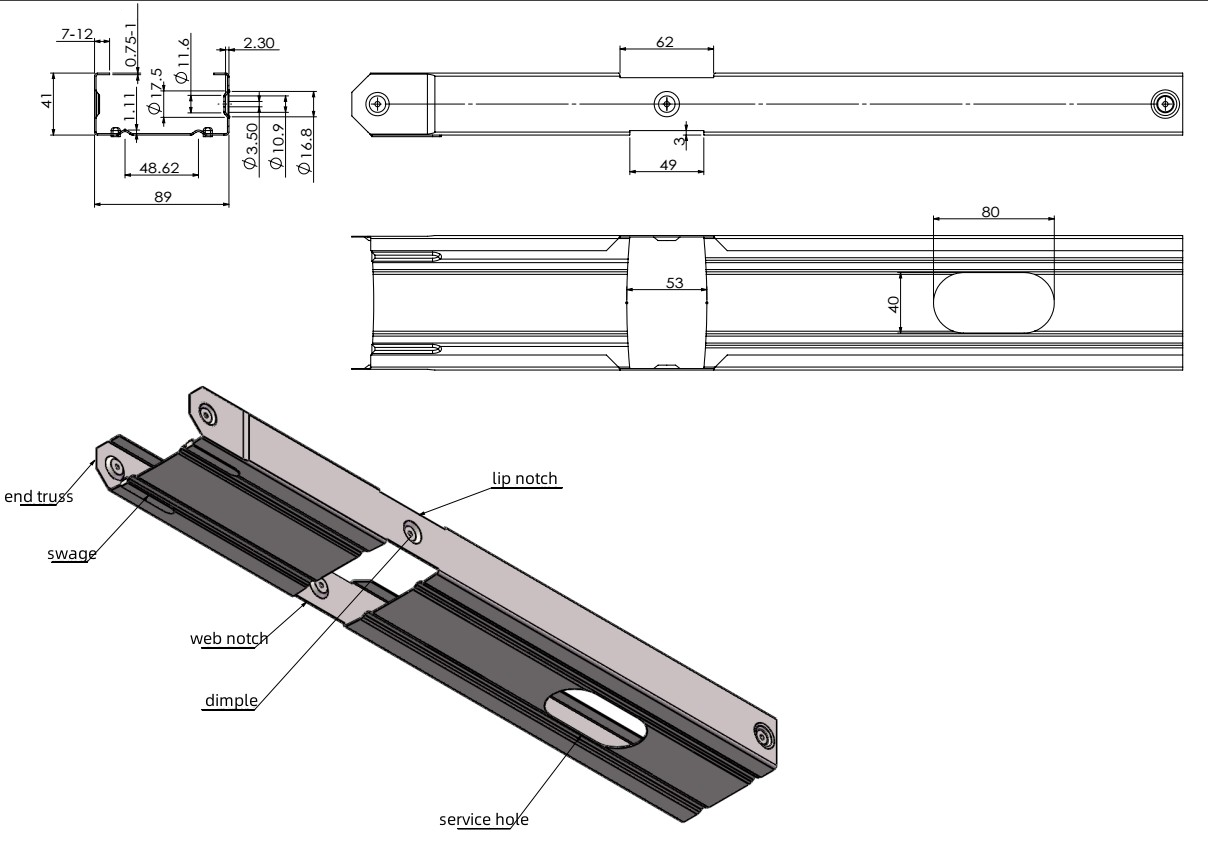

| Portable Light Gauge Steel Framing Machine Q5 | No:Q5 | Specifications:89*41*10 | ||

| Device configuration parameters | ||||

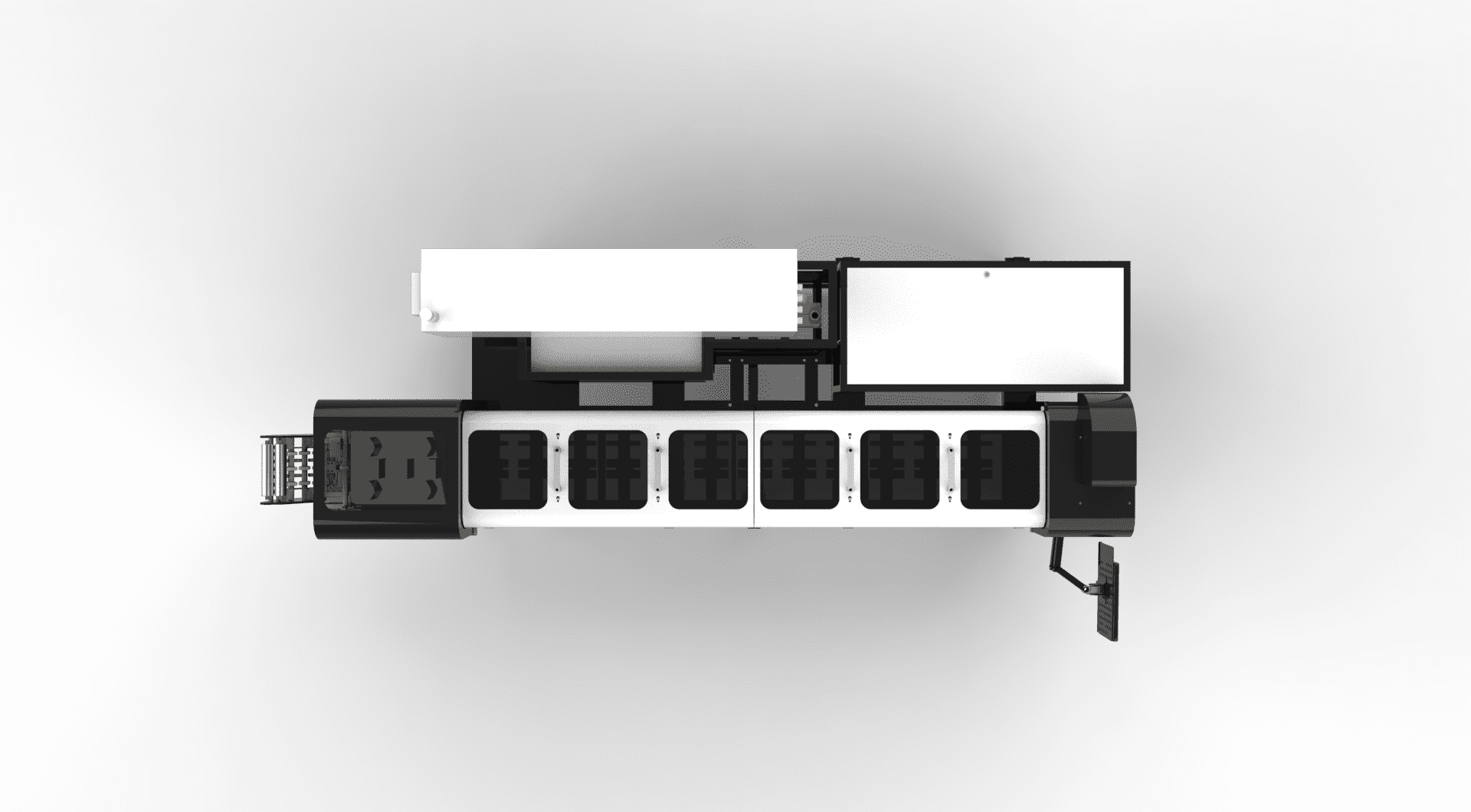

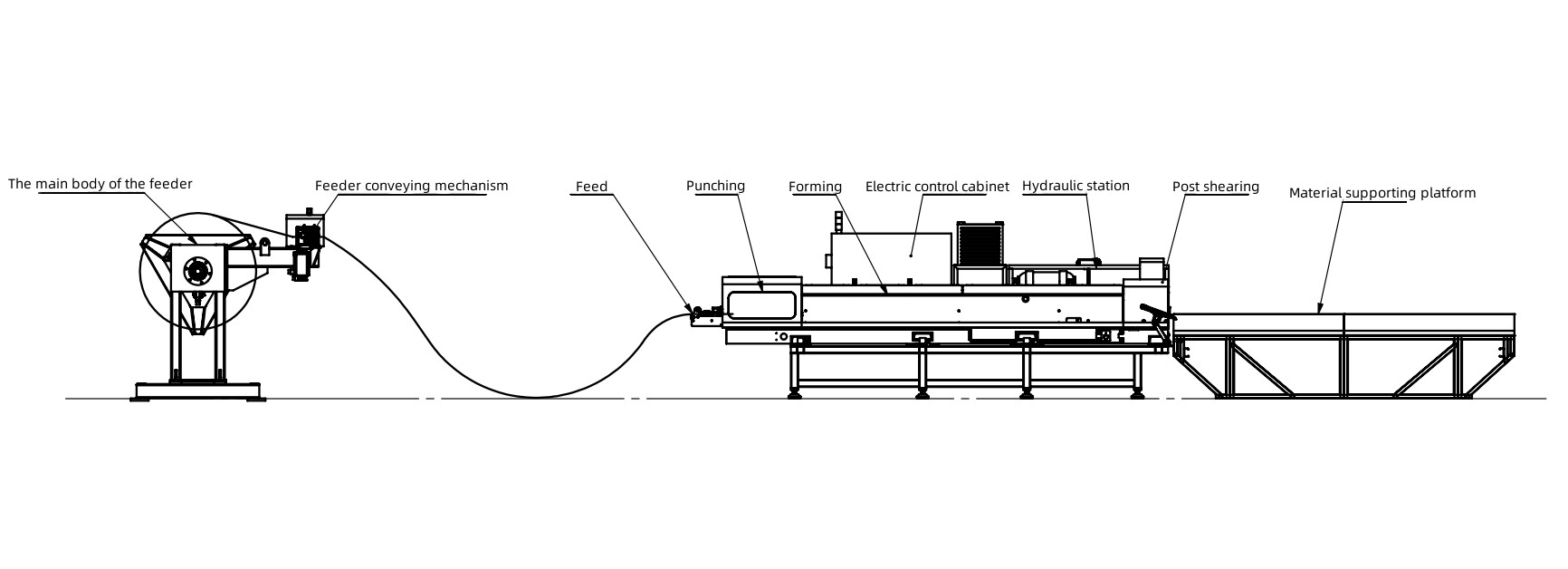

| Forming host | Feed | Upper and lower rollers+two groups of backup rollers | ||

| Main forming | 132 Composition type (one of which is waist height forming 87-95 degree random roll adjusting group) | |||

| Straightening | Two shaft and two lean assembly | |||

| Piloting | Equipped with transmission, upper and lower shaft gear drive | |||

| Punching | ||||

| Shear | Three piece cutter cutting | |||

| Other | Equipped with shaping rear waist high active traction system | |||

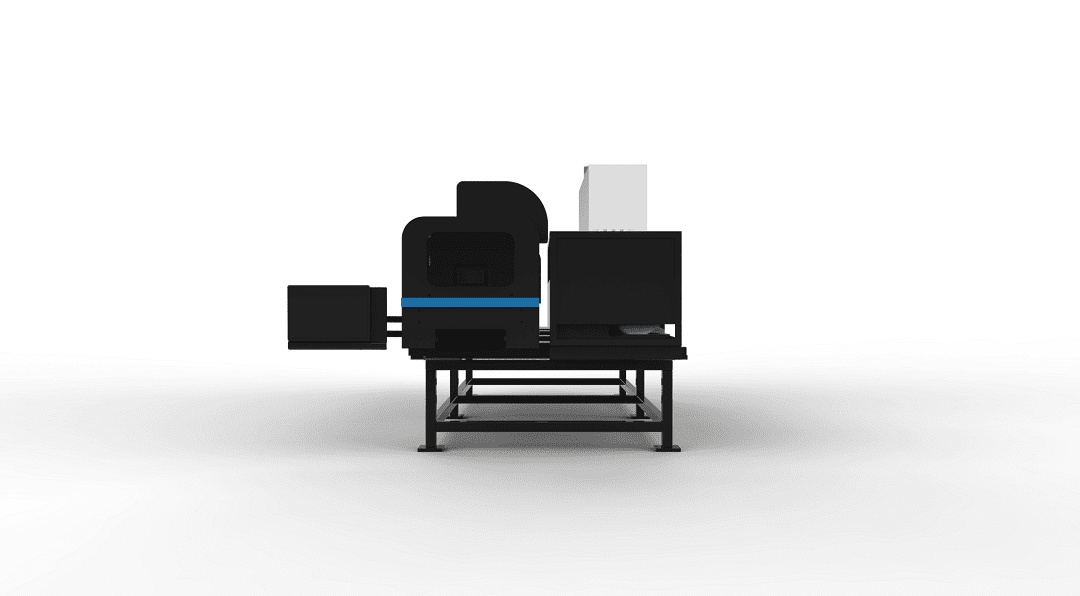

| Control system | Main control cabinet | Notebook (installed at the discharge end of the equipment)+1 electrical main control cabinet (installed at the side of the equipment) | ||

| control software | LG-R1 (special NC control software for Dahe Zhongbang Light Steel Villa) | |||

| Inkjet code | Integrated inkjet (single nozzle) | |||

| External controller | Wireless remote control control, and emergency stop buttons are set on the front and rear shields of the equipment; | |||

| Origin of main parts | PLC (Panasonic, Japan), photoelectric switch (Omron), proximity switch (Otonix, South Korea), length encoder (Omron), servo motor (Huichuan) | |||

| Control system | Servo motor | Servo motor (4.4KW)+precision planetary gear reducer (Taiwan APEX) | ||

| Hydraulic station | Power of hydraulic station: 4KW | |||

| Fuel tank volume 120L | ||||

| Origin of main parts | Solenoid valve Rexroth | |||

| Discharger | Load | 2 tons | ||

| Bracing method | Hand crank connecting rod type, with the center supporting outwards | |||

| Brake | Double locking of main shaft | |||

| Drive | Feeding driven by 1.8kw servo motor | |||

| Maximum coil outer diameter | 1000mm | |||

| Material supporting platform | Supporting material length | 4m | ||

| Material holding method | Fixed pallet+storage platform | |||

| Material supporting platform | roll | Material: GCr15 | ||

| Processing technology: heat treat to HRC58-60 after CNC processing, and then finish turning, polishing and electroplatin | ||||

| axis | Material: 40Cr | |||

| Processing technology: after CNC processing, hrc28-32 is quenched and tempered, and then polished and electroplated | ||||

| weight | The total weight is about 2.65tons | |||

| Performance parameter | ||||

| 1.Product specifications | 1. Width 89mm; 2. Waist height 41mm; 3. Small edge 7-12mm; 4. The plate thickness is 0.75-1.2mm; | |||

| 2.Exit speed | High speed 48m/min (actual production speed depends on the number of holes punched) | |||

| 3.Material applicable | G550 galvanized strip steel | |||

| Attached accessories and spare parts | ||||

| 1 | Spare part | Attached list | ||

| 2 | Instructions | The electronic file is integrated in the control software | ||

| 3 | tool | a set | ||

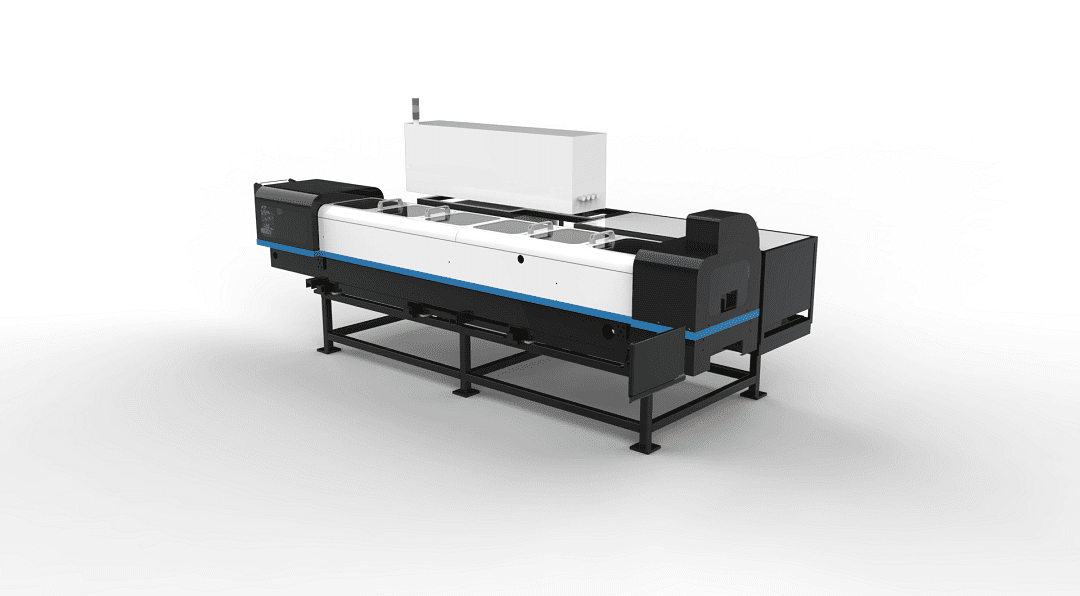

| 4 | Shield | Totally enclosed protective cover | ||

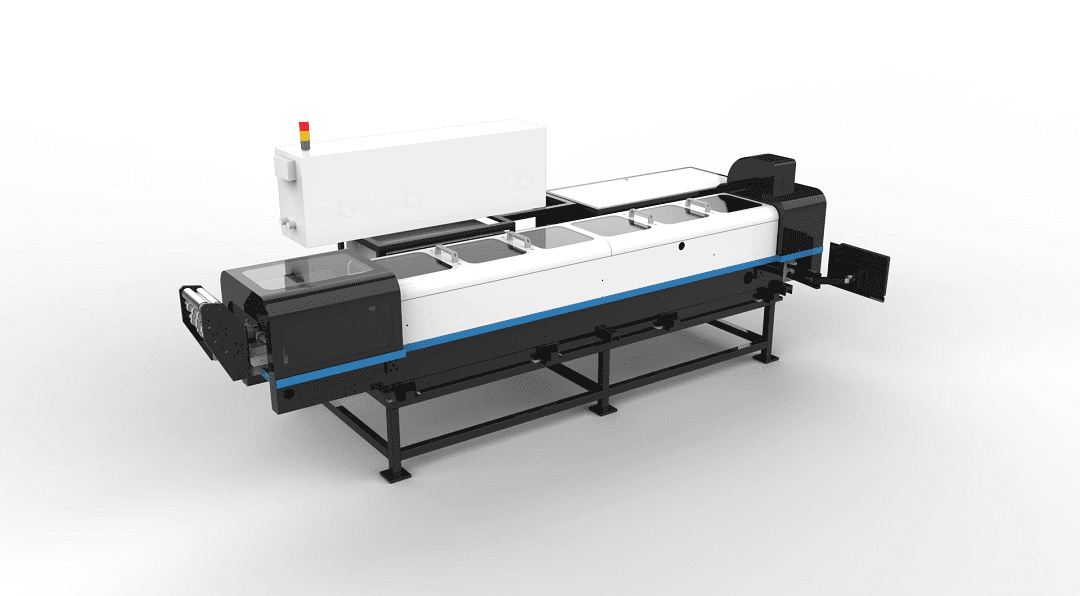

| 5 | Device color | Body color: ivory white+dark blue, waist line: light blue, rack: black, black transparent acrylic window | ||