Component and Function

1. Sheet guiding equipment: Using guiding equipment of leader sliding block style. The width and the left or right position can be adjusted only by adjusting the leader, then the sliding block can realize left or right movement.

2. Mainframe Transmission: Transfer the main motor power to the rollers through chains and sprockets, and also transfer the coil sheet.

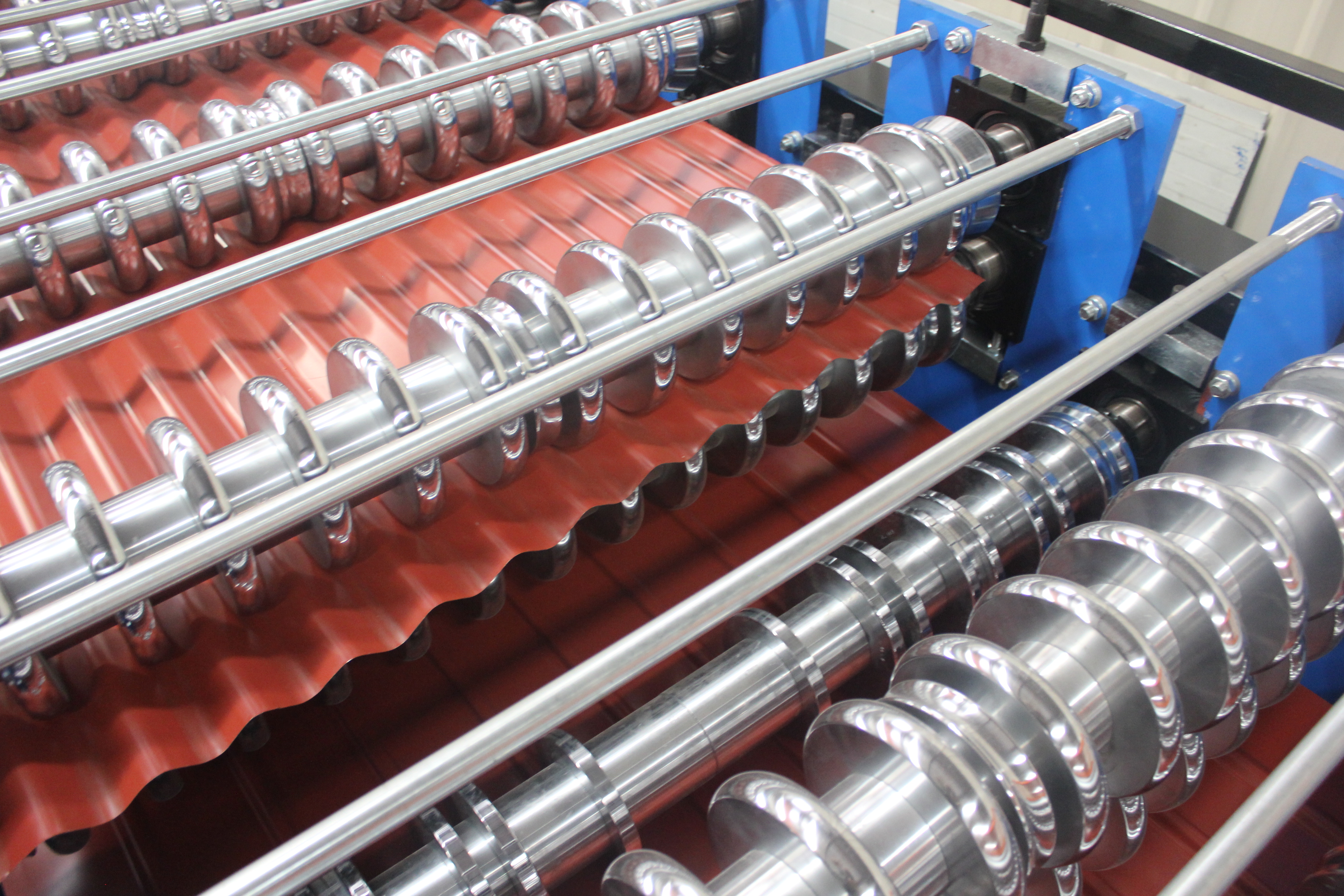

3. Roll forming system: The main frame of machine is welded separately and the outside wall is connected by screw after being roto-blasted on the surface. The rollers are surface-chrome plated after being machined by the exact machine tool.

Product Advantages

1).Take the EUROPEAN Quality Standard;

2). Choose the Best Material and Components.

3). Over 15-Year-Experienced Experts and Top International Sales to Care Your Needs.

4). Offer The Highest Quality but The Best Price in Prevailing Market.

5). Customize for You.

Product Features

1.Certificate: ISO 9001, CE,

2. Lifetime services

3. Introduced Mitsubishi PLC with touch screen to machine controll system.

4. Roller cover with 0.05mm chrome; 82mm diameter solid steel shaft. Lifetime>10years.

5. One worker operation (minimum)

6. Heat treatment:Cutting blade. Quenched treatment: Cr12 mould steel cutter

7. Product cut-to-length.

8.Technician overseas installing and training available

Designated use

1. Some final products for Automobile.

2. Some final products for Building, such as for Roofing / Ceiling / Wall materials, and dry wall (track and stud) material.

3. Some final products for Gate-Panel, Guard-Panel and sound insulation

Parameter

| Item | Specification | |

| Material | Type | Pre-painted steel coil & galvanized coils |

| Thickness | 0.3-0.7mm | |

| Yield strength | 235Mpa or 550Mpa | |

| Roller material | No.45 forged steel, with hard chrome coating 0.05mm | |

| Forming speed | About 20m/min | |

| Speed adjusting mode | AC Frequency | |

| Roller drive | Decelerating motor + Chain drive | |

| Cutting mode | Hydraulic cutting | |

| Cutter material | Cr12 mould steel | |

| Length measurement | Encoder | |

| Control mode | Mitsubishi PLC | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Main motor | 7.5KW | |

| Hydraulic station motor | 2.2KW | |

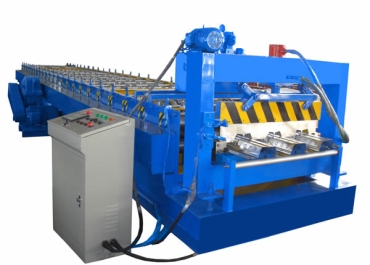

Machine components

| Decoiler (manual/ hydraulic decoiler for option) | 1set |

| Feeding & guiding device | 2set |

| Main roll forming machine | 2set |

| Hydraulic cutting system | 1set (2 blades) |

| Controlling system | 1set |

| Run out table (auto. Stacker for option) | 1.5m/ pc, 2 pcs |