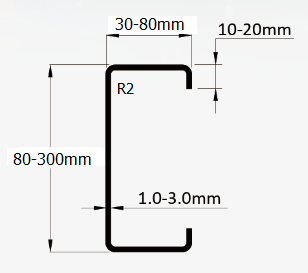

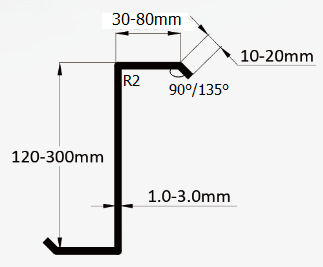

Purlin Specification

Material: cold rolled coil, hot rolled coil, galvanized coil

Yield strength: Q195, 235B

Coil Thickness 1.0-3.0mm

1)Product Spec

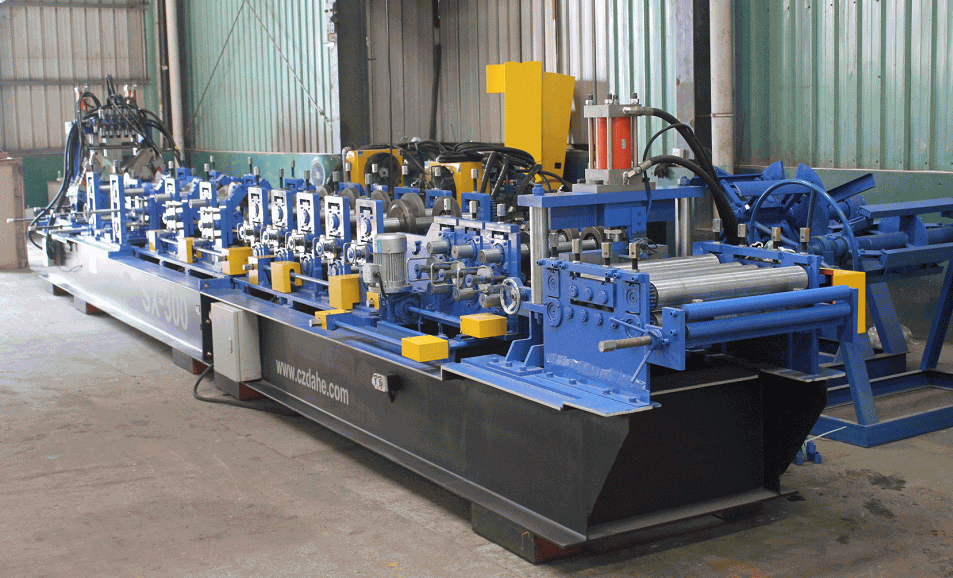

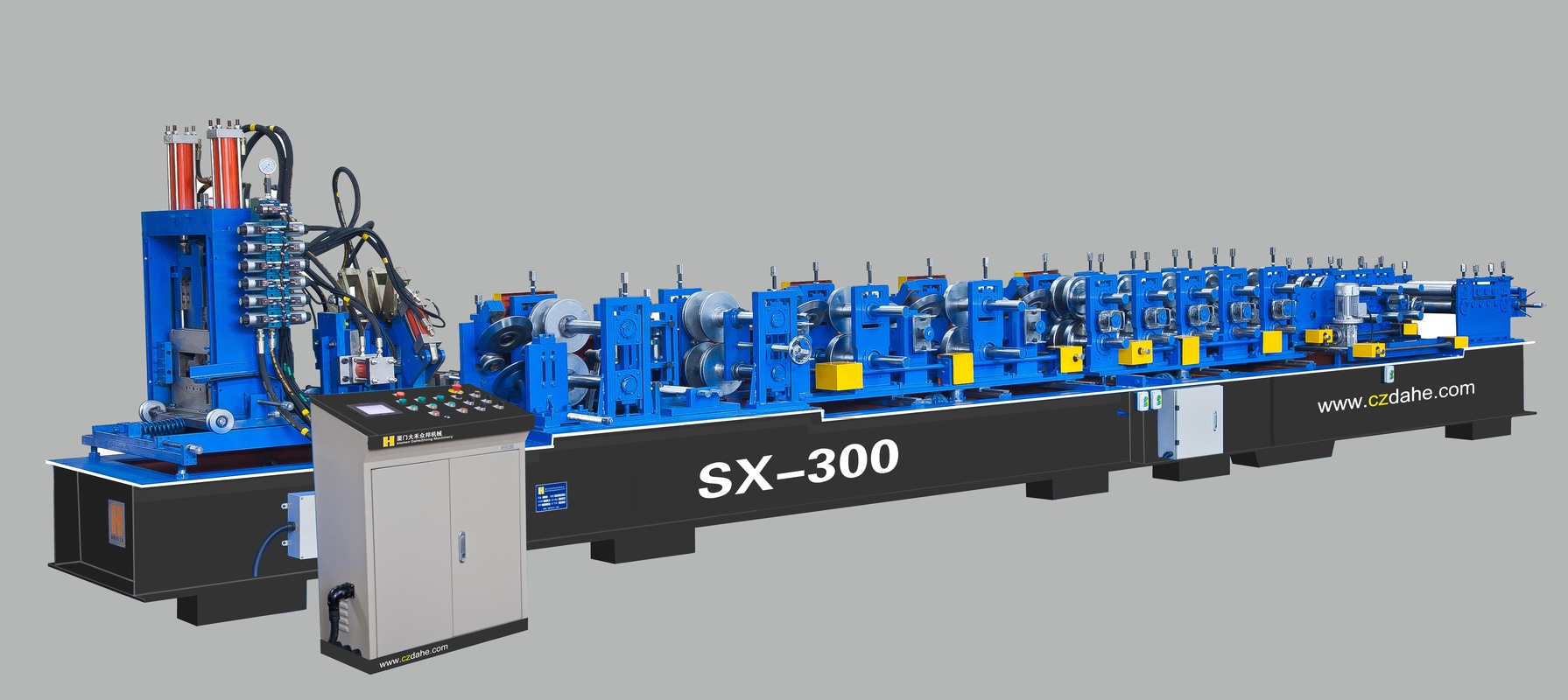

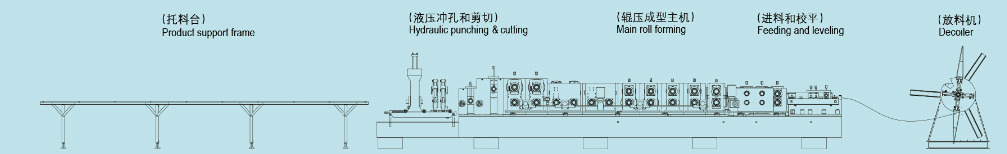

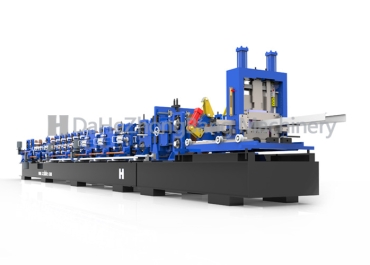

Flow Chart

De-coiler – Feeding and Leveling device —Roll Forming System- Post-punching system– Post Cutting – Hydraulic station – PLC – Cutting Product Support

Machine Components

1.De–coiler

De-coiler Type: Manuel de-coiler

Weight capacity: 6.0T

2.Feeding and Leveling Device

Material: GCr15, It used for making the material flat before feeding into the roll forming machine.

3.Pre-cutting system

This cutter is for last piece cutting. Cutting controlled by PLC

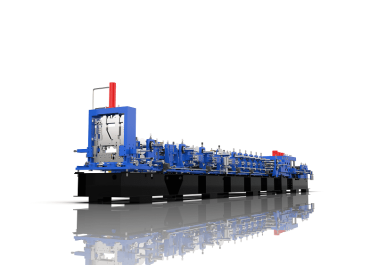

4.Rolling Forming System

Main motor type: 3 phase asynchronous motor

Driving Type: Chain

Roller: 19groups rollers. Main rollers of this line are made by Cr12 mould steel material, all treated by full CNC precision machines

Shaft: Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

Material of main shaft: NO.45 steel

Quick Change from C to Z

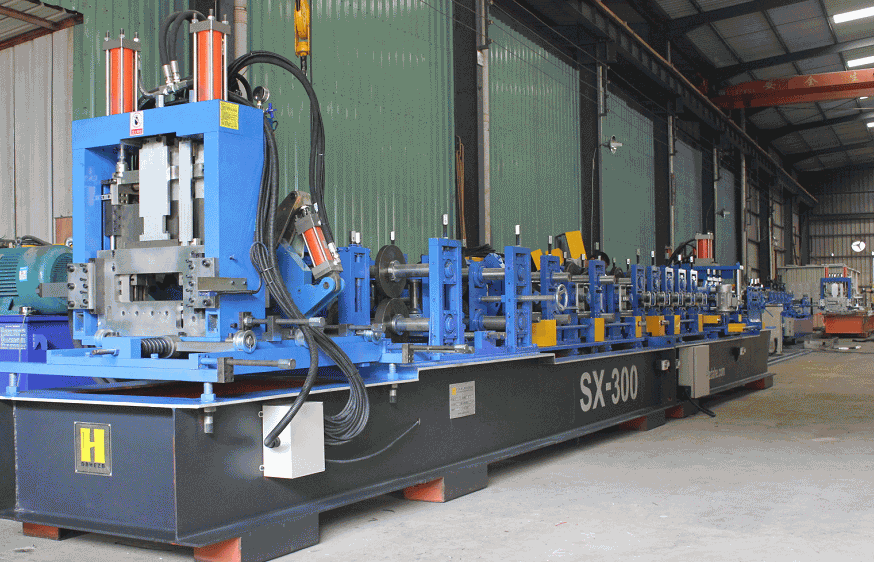

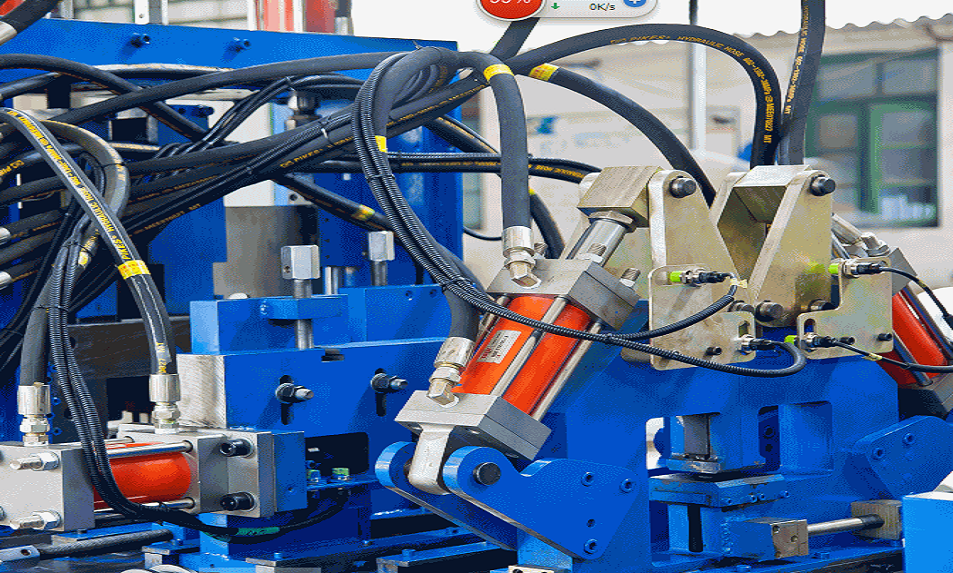

5.Post Punching System

Punch on roll formed product. PLC control punch quantity and horizontal position; vertical position adjust by manual Punching sizes can be changed;

6.Post-cutting system

Cutting type: Hydraulic cutting

Blade cutter material: Cr12

For C and Z profile cutting

7.Product Support Frame

8.PLC Control System

Control the quantity &punching length & cutting length automatically

PLC must be able to keep in memory which profiles are “inside” the machine even after the machine is stopped.

Automatic Length measures and quantity counting.

Program batches with different profile lengths with no waste