TECHNICAL PARAMETERS

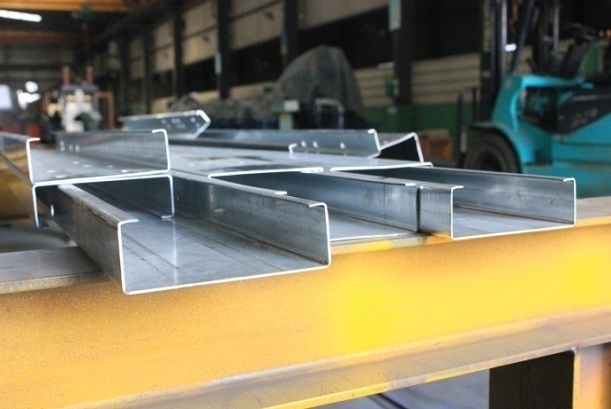

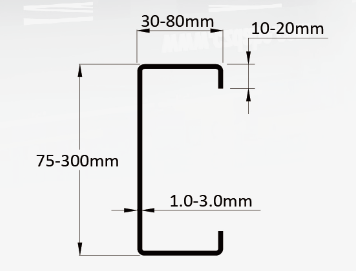

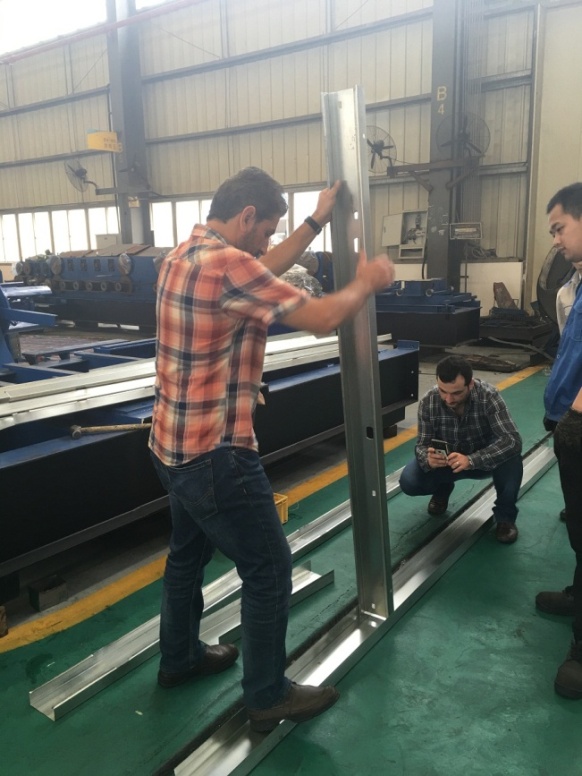

Ⅰ.PURLIN SPECIFICATION

- Material:hot coil, galvanized coil

- Thickness: 1.0-3.0mm

- Product Spec – Width in any size within 75-300mm

– Flange in any size within 30-80mm

– Lip in any size within 10-20mm

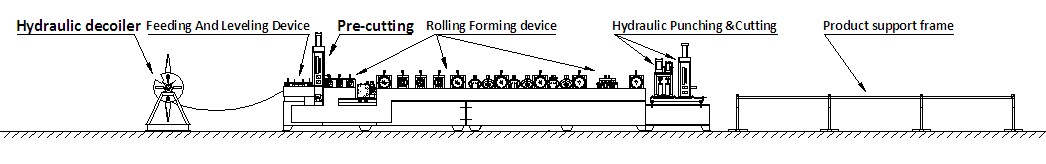

FLOW CHART

Decoiler→ Feeding and leveling →Pre-cutting →Roll forming→ Post cutting→Hydraulic cutting→ product support frame

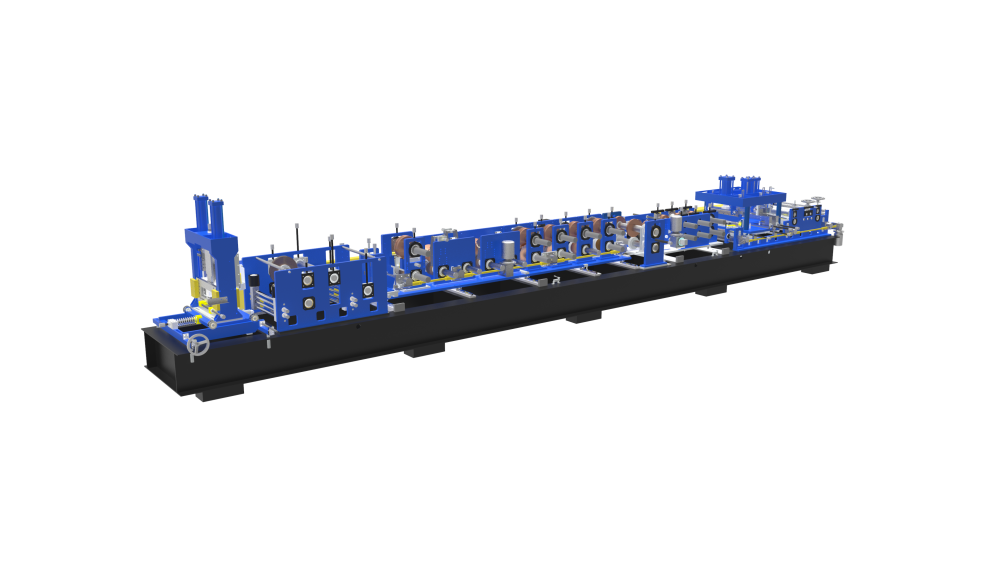

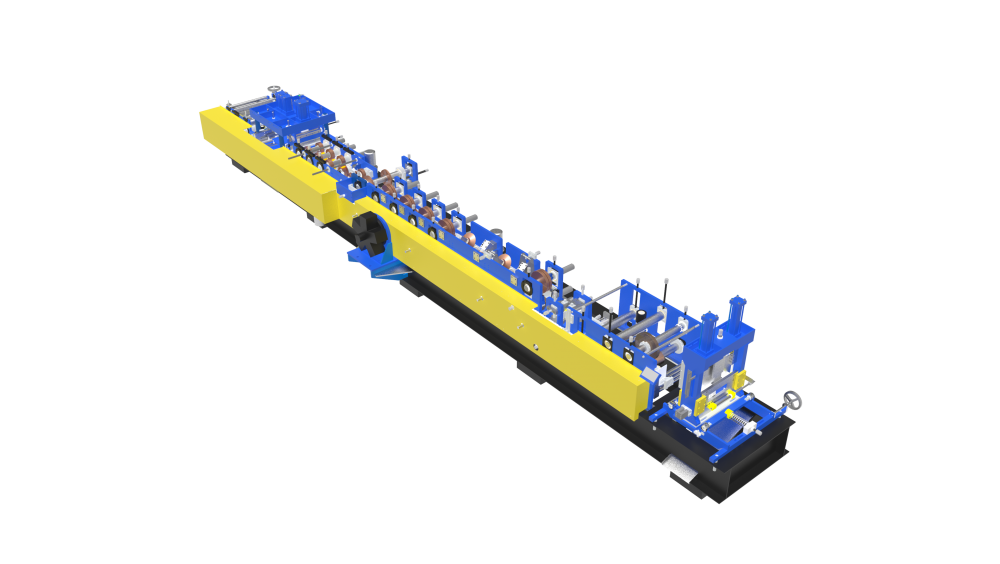

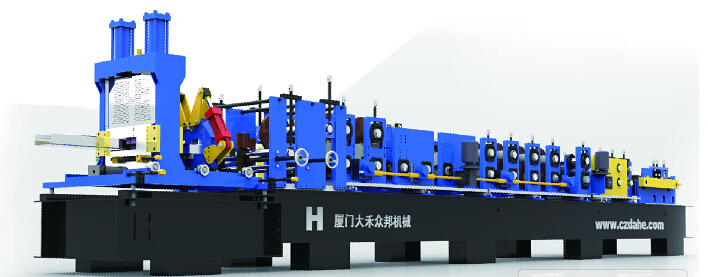

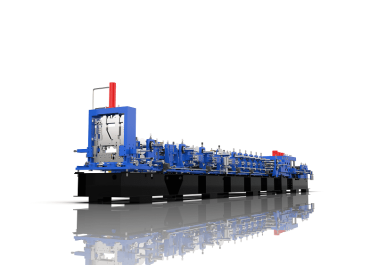

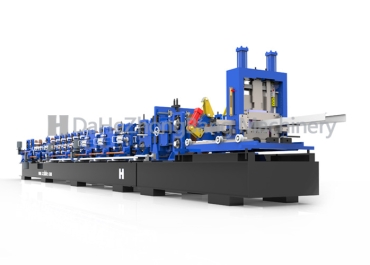

Machine components

1)Decoiler

Decoiler Type: Manual decoiler

weight capacity of decoiler : 5.0T

2) Feeding and levelling

Entrance and guide roller: 7 rollers Up 3 down 4

3)Pre-cutting

It used to cut raw materials before roll forming and last piece.

4)Roll forming System

Motor power: 18.5KW

Speed of forming: 30m/min(without punching and cutting)

Roller: 17 groups rollers. Roller Material is Cr12

Material of main shaft : 40Cr

Changing sizes: Automatically by pressing button

5) Post Punching

Punch on roll formed product. PLC control punch quantity and horizontal position

6)Hydraulic cutting

- Cutting type: Hydraulic cutting

- Cutting material: Cr12 Cr12MoV Cr12(total three blades)

7)Product support frame: 6m

8)PLC control system

Control the quantity &punching length& cutting length automatically

The Machine will be stopped while it is punching and cutting

Automatic Length measure and quantity counting