Quick details | ||

Model number: NL300 | Condition: New | Work Pressure: |

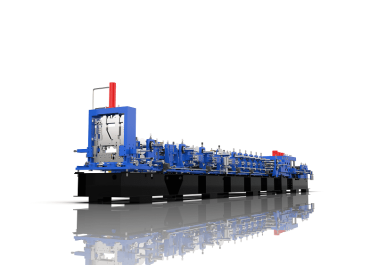

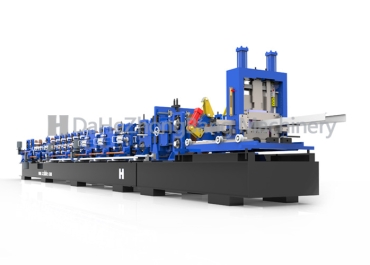

Type: C/Z Purlin machine | Place of Origin:Xiamen, China | Brand Name: dahezb |

Production Capacity: 8-15M/min | Voltage: 380V | Power(W): 11KW |

Dimension | Weight: | Certification: ISO CE |

Warranty | After-sales service | Machine Function: CZ purlin forming |

Machine running | Appearance: | Control System: PLC |

Decoiler | Cutting blade: Cr12 | Color: Blue |

Features of C/Z purlin machine:

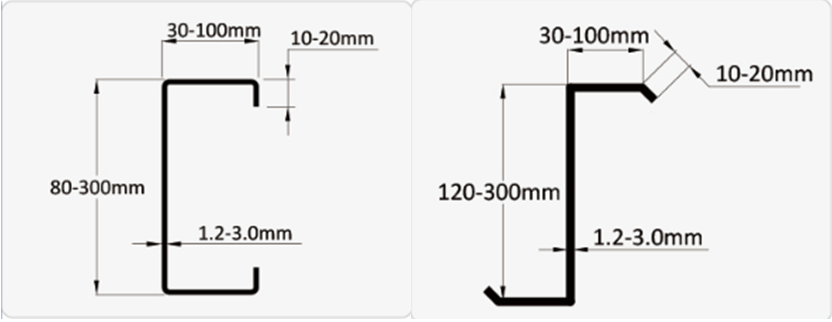

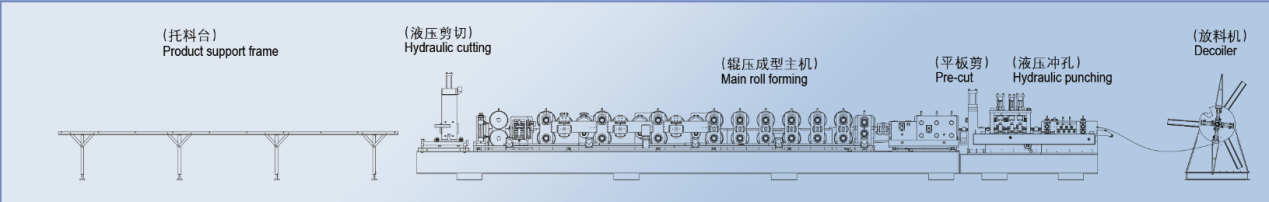

Our NL300 C/Z purlin machine consists of decoiler, feeding and levelling device, punching system, pre-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system). Its special quick change feature: Assemble with liner guide way to make machine change web size easily and smoothly

Produce standard products with yield strength up to 345Mpa,Long production line,no open mouth on final products, C/Z interchange only with 3 steps and within 5-15mins; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

Flow chart: De-coiler – Leveling device — pre- punching and pre-cutting – roll forming parts – stack

Main Components:

1.Mechnical decoiler 1 set (can be updated to hydraulic decoiler)

2.Feeding and leveling

Entrance and guide roller, Material 40CR, HRC28-35 surface chrome plated

3.Pre-punching device

Punch on flat sheet. PLC control punch quantity and horizontal position; vertical position adjust by manual. Punching die raw material is Cr12. Punching holes quantity and size are as per customer`s request. Punching bar and punching die can be changed easily.

4.Pre-shear equipment

It used to cut raw materials before roll forming.

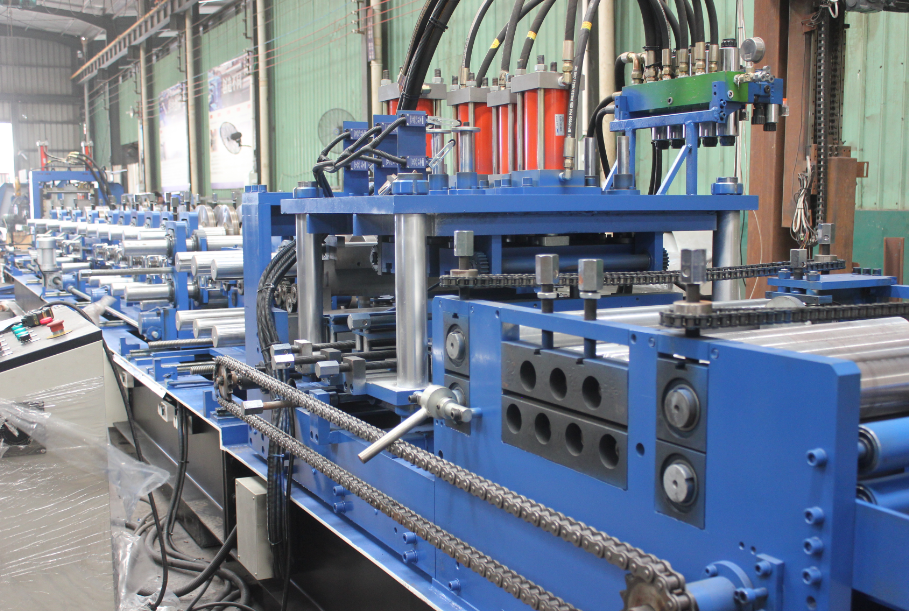

5.Main roll forming

Machine base frame adopt H beam welding steel

With leveling bolts in the base to adjust the leveling

Transmission type: by chain

Main motor type: 3 phase asynchronous motor

Speed of forming: 0-30m/min

Roller Material is Cr12 mould steel, 21 groups rollers.

Material of main shaft: 40Cr Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product. Diameter of main shaft: ø75-85mm

Changing purlin size automaticly

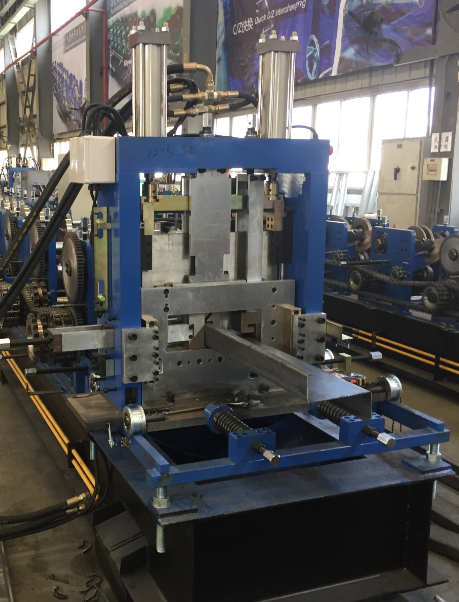

6.Hydraulic cutting device

Adopt our innovative cutting system, CZ integrated & adjustable cutting mold do not need to replace cutting mold when purlin sizes changed.

7.Product support frame

Size: L 6m x W 0.5m

Qty: 1

8.PLC Control System

Control the quantity &punching length& cutting length automatically

The Machine will be stopped while it is punching and cutting

Automatic Length measurement and quantity counting (precision 3m+/- 2mm)