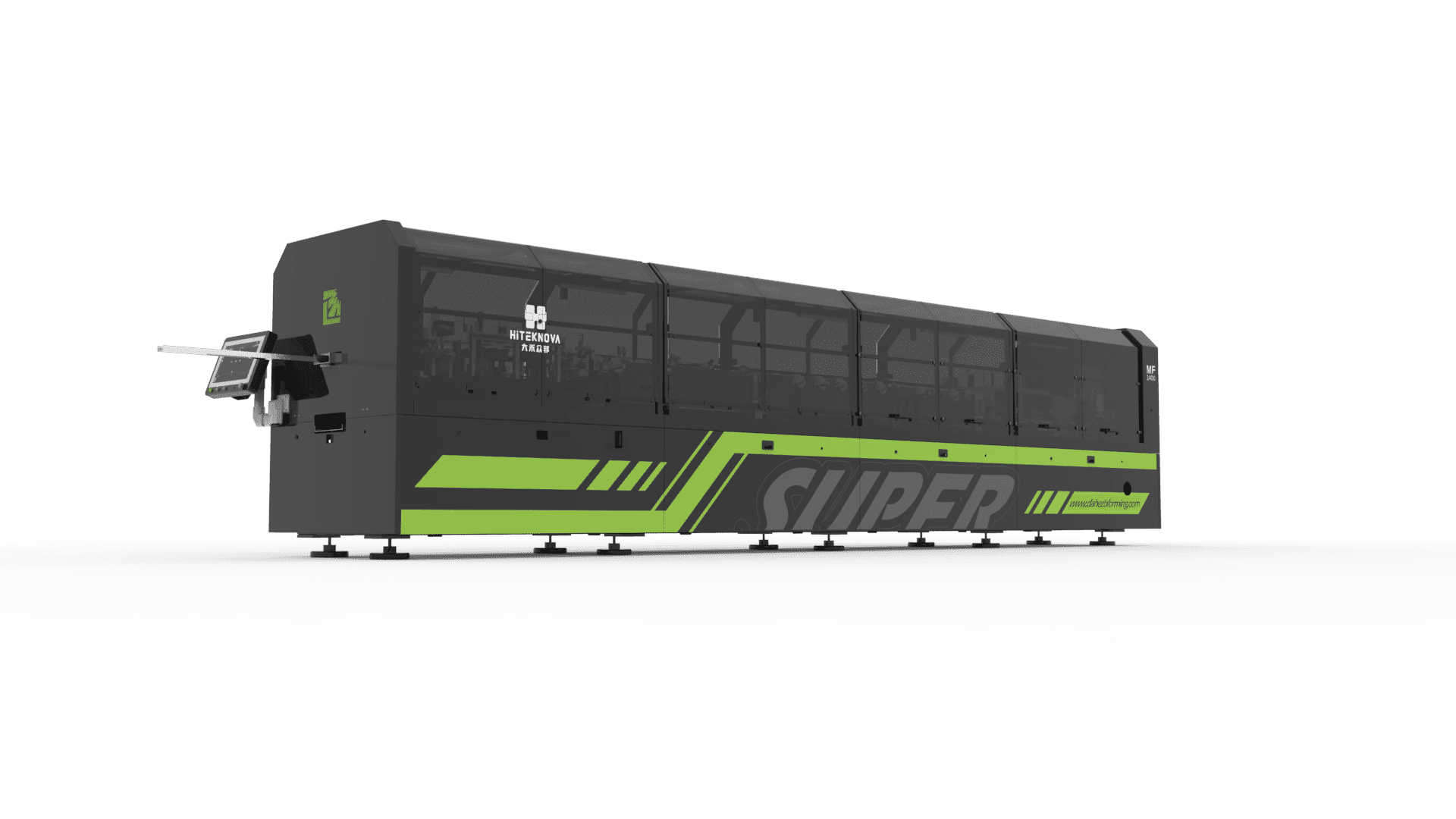

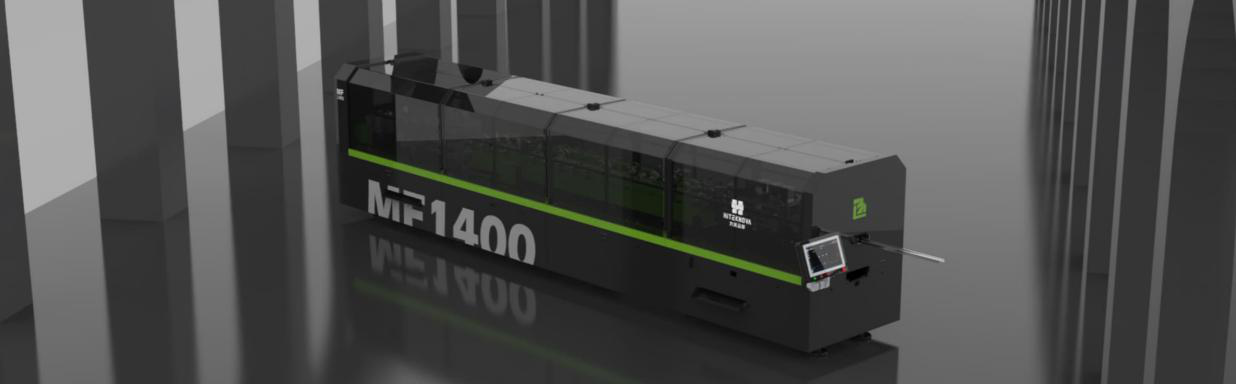

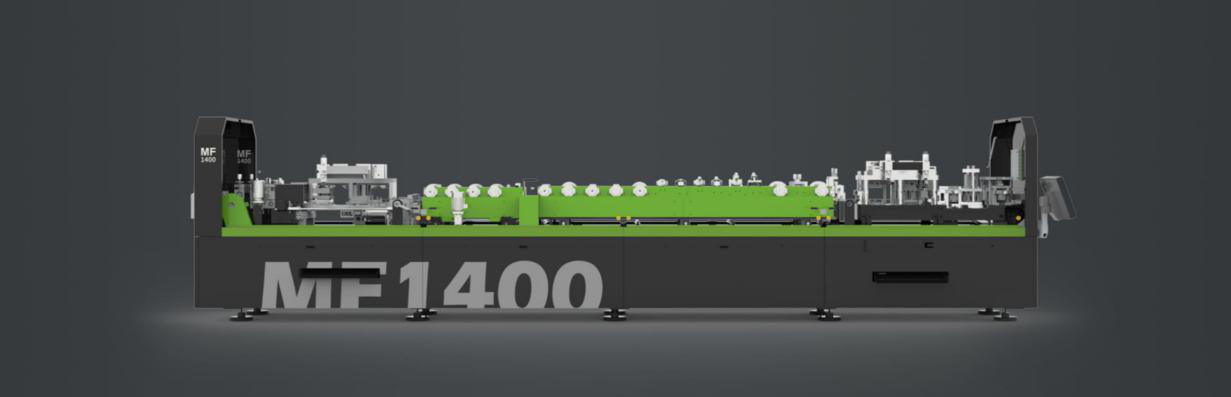

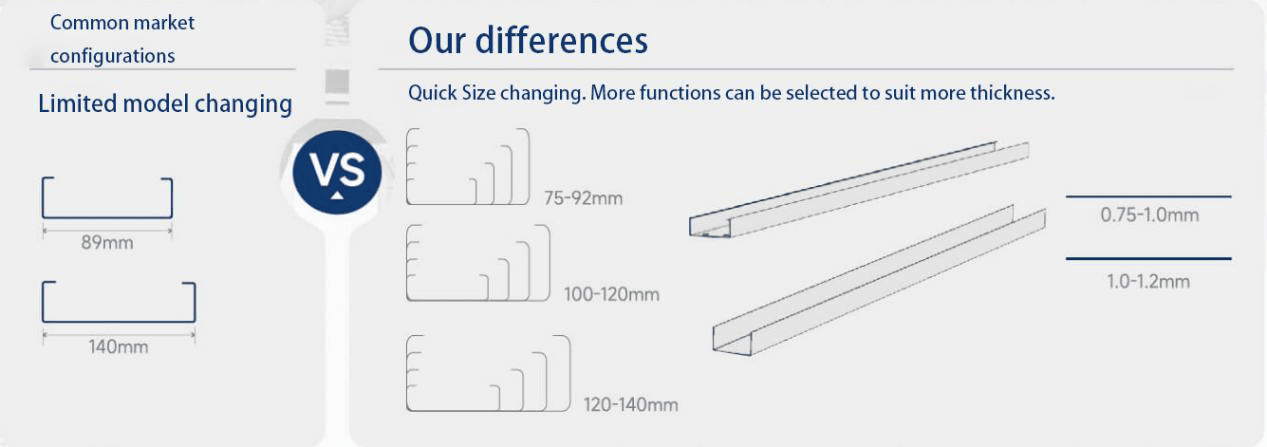

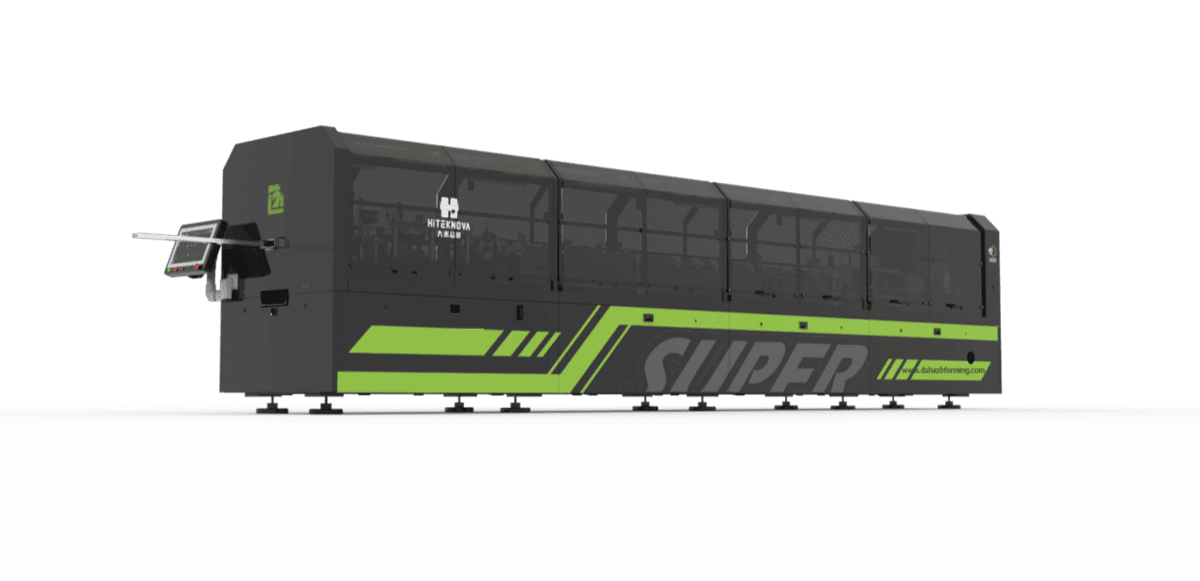

The MF1400 model from Hiteknova, which combines the advantageous features of the LG series, is a highly capable machine. It can manufacture two specific types of section steel systems, namely CC and CU, with a size range spanning from 75mm to 140mm. Notably, the accuracy of the final products can reach an impressive +/- 1mm. It can quickly adjust the plate type and automatically adapt to the plate thickness, ensuring the diversity and precision of the production specifications of light steel keels.

Specifically designed to meet the requirements of one to three-story houses, villas, partition walls, and ceilings, the MF1400 is extremely well-suited for various residential, commercial, and industrial projects. It truly stands as a reliable and adaptable solution across multiple sectors.

Specification

- Web Width:75/89/140mm (95″/3.5″/5.51″), vary arbitrarily in this range;

- Flange Height:41mm (1.61″);

- Lip Width: 8~12mm (31″-0.47″);

- Max Material Thickness:75~1.2 mm (0.029″-0.047″)adjustable.

Technology Parameters

| Description | |

| Machine Weight | 8T |

| Profile Shape | CC and CU |

| Section steel material | Q235,Q345,G550,Hot-tied galvanized strip steel |

| De-coiler | Manual automatic de-coiler |

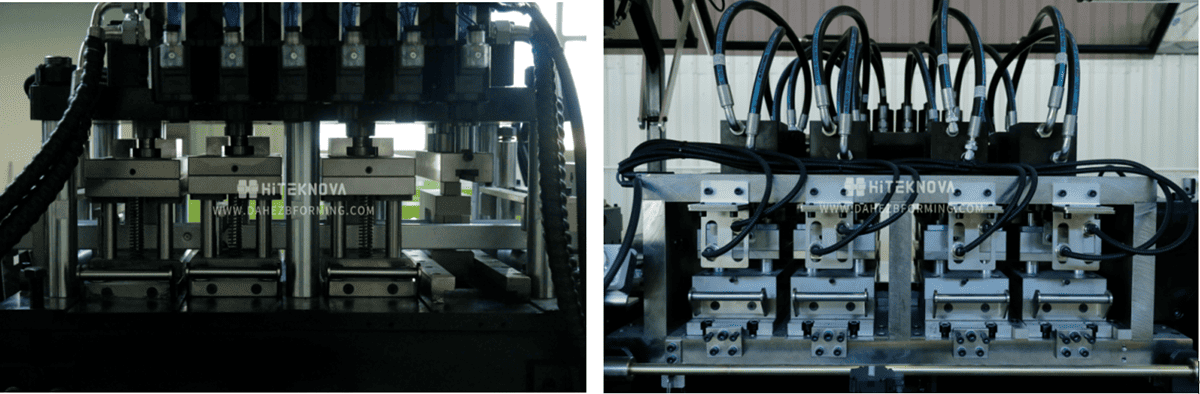

| Hole Punching | Hydraulic punching |

| Hole Punching Accuracy | ± 0.5 mm |

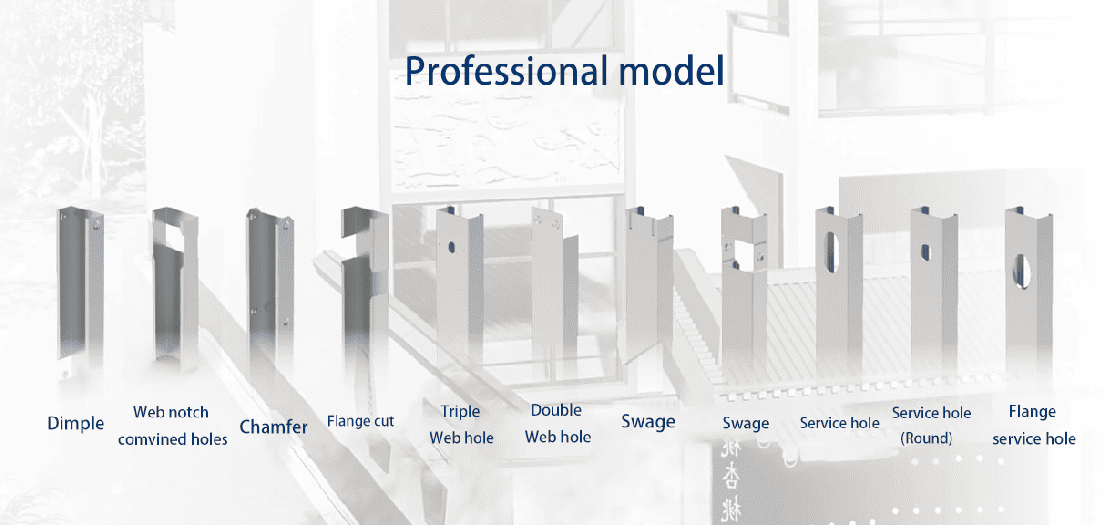

| Hole Type | End Truss, Dimple, Web Notch, Service Hole, Web Hole, Flange Dimple Hole, Cut ,Swage |

| Plate Speed | High speed 35m/min, (the actual production speed depends on the number of punched holes) |

| Online Printer | Marks and Item Number |

| Out-let Table | 4 meters |

| Main Control Cabinet | 2 electrical main control cabinets |

| Touch Screen | 21-inch |

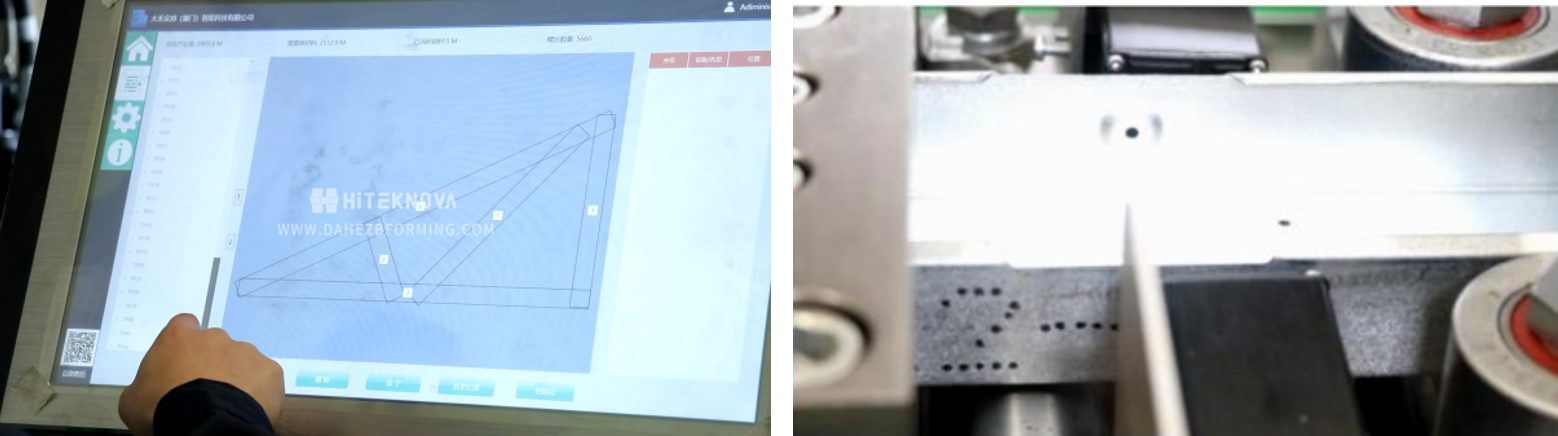

| Controlling Software | LG-R1 |

| External Controller | Wireless remote |

| Voltage Power | 380V 50hz |

| Drive Motor Power | Servo motor 11KW |

| Fuel Tank | 200L |

| Machine Colors | Gray |

| Free Spare Parts | Other easy wear parts |

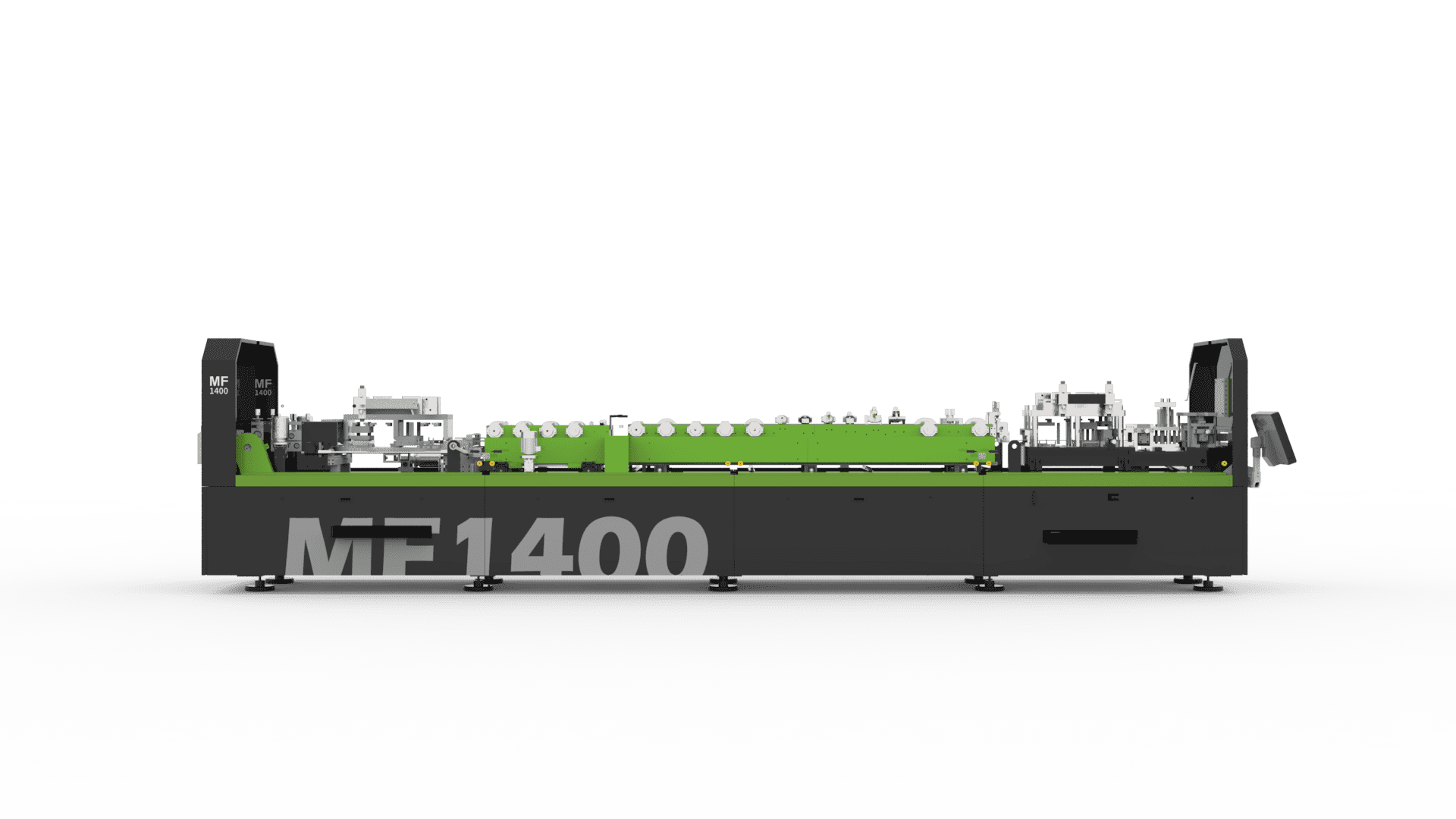

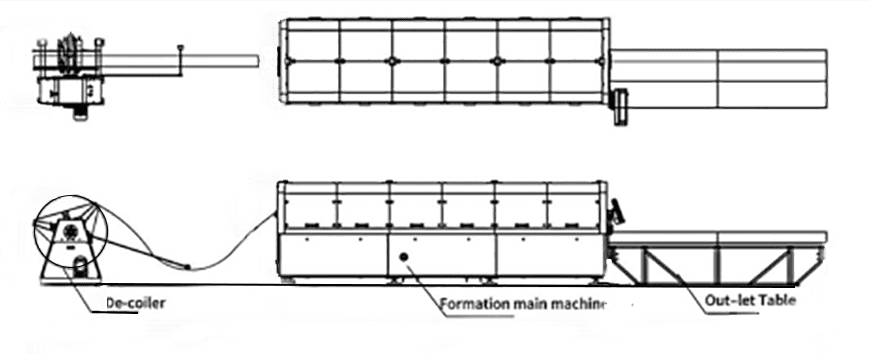

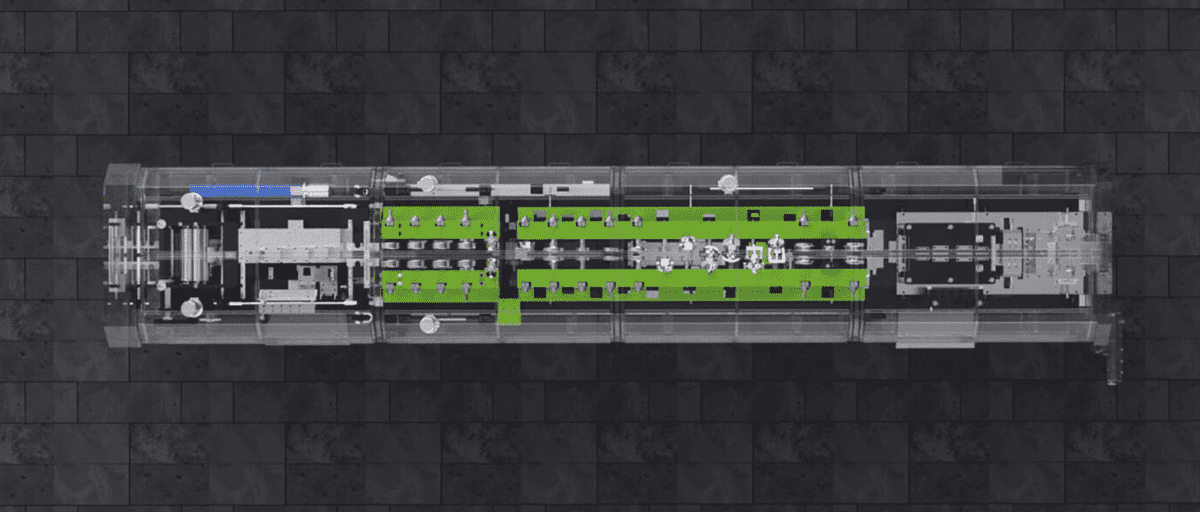

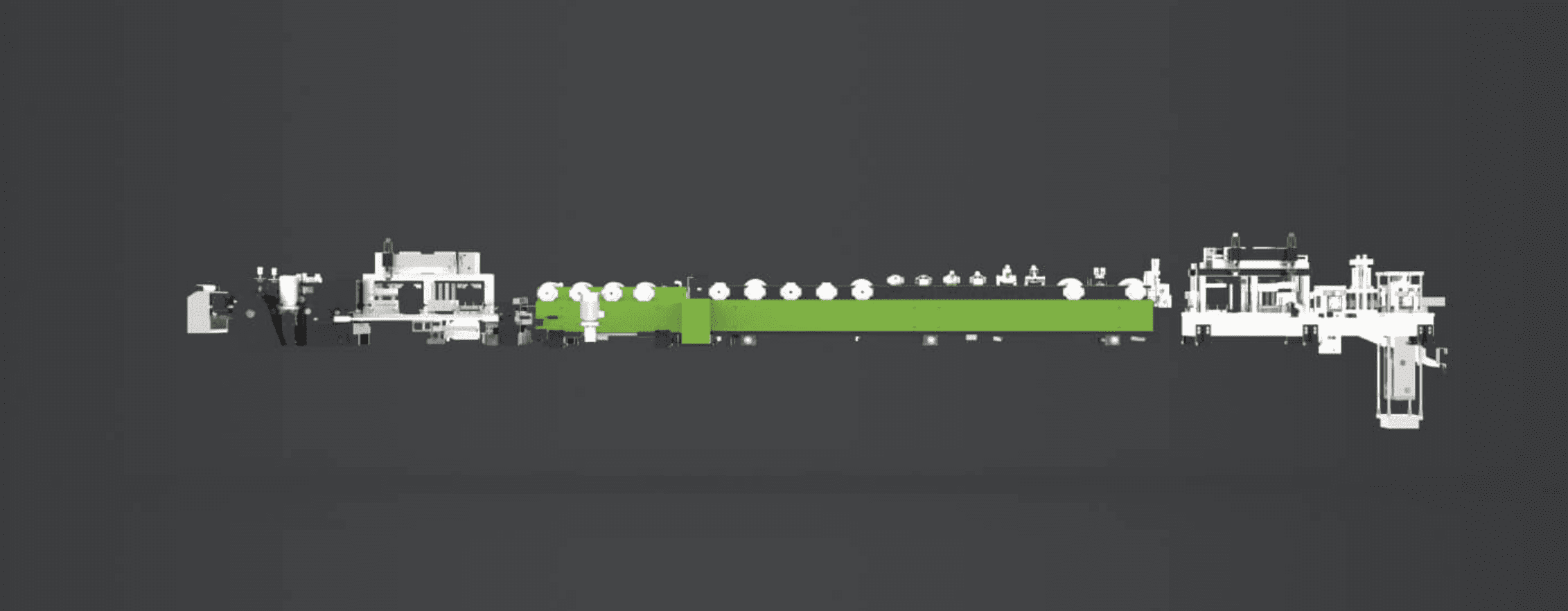

Flow chart

De-coiler→ Leveling Device→ Punching Device→ Roll Forming System → Punching Device and Cutting Device →Out-let table

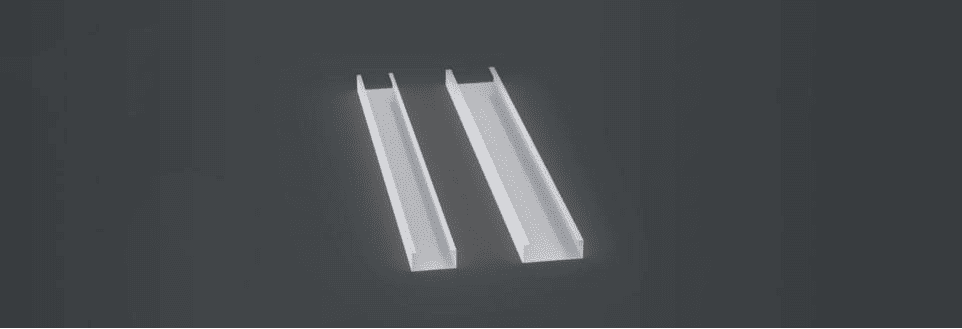

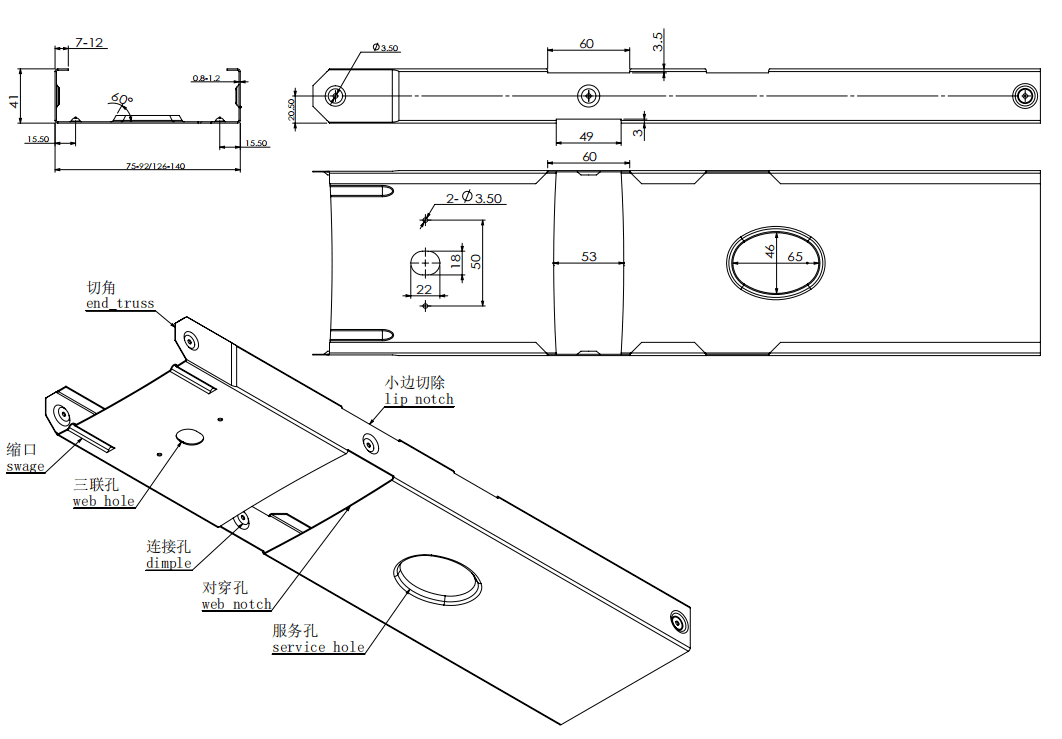

Profile Drawings

| Standard Metric Sizes | |

| Web Width | 75-92mm,100-120mm, 126-140mm |

| Flange Height | 41mm |

| Lip Width | 8-12mm |

| Max Material Thickness | 0.75-1.2 mm |

| End truss | 20.5mm |

| Lip Cut | 60mm |

| Swage | 15.5mm |

| Web Hole | 20*18mm |

| Dimple | 0.8-1.2mm,Φ3.50 |

| Web Notch | 53mm |

| Service Hole | 65*46mm |

| Standard Imperial Sizes | |

| Web Width | 2.95″-3.62″,4.96″-5.51″ |

| Flange Height | 1.61″ |

| Lip Width | 0.31″-0.47″ |

| Max Material Thickness | 0.029″-0.047″ |

| End truss | 0.80″ |

| Lip Cut | 2.36″ |

| Swage | 0.61″ |

| Web Hole | 0.78″ X 0.7″ |

| Dimple | 0.031″-0.047″, Φ0.13″ |

| Web Notch | 2.08″ |

| Service Hole | 2.55″X 1.81″ |

- Custom Service Holes size available on request

- Custom Bolt Hole sizes available on request

- Custom Web Holes size available on request

- Custom Lip cut available on request

- Plate speed: high speed 35m/min, (actual production speed according to the number of holes)

- Material application: Q235, Q345, G550 hot-tied galvanized strip steel

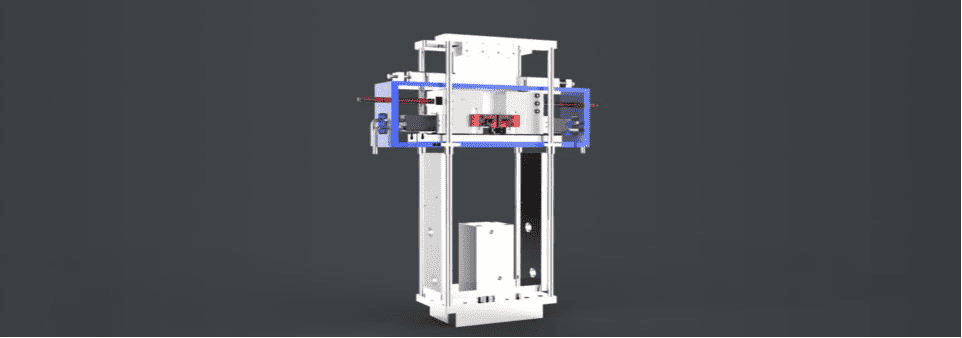

Machine Detail

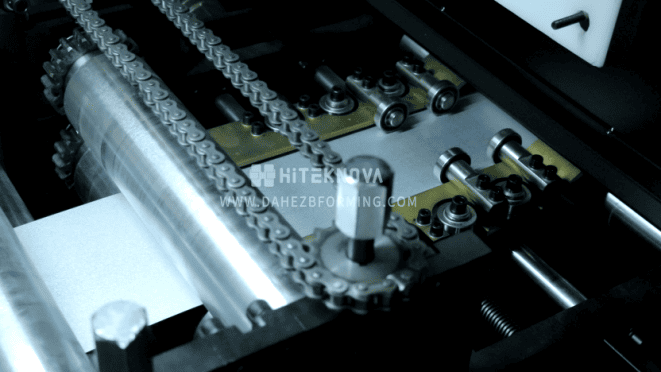

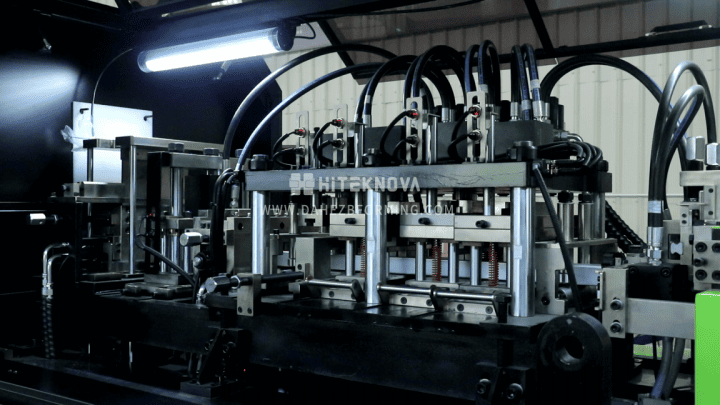

High quality and agile leveling device is used to ensure smooth material entry and material leveling.

Equipped with standard die: 75-92,126-140mm, support a variety of pass use:End truss, Lip notch, Web hole, Service hole, Dimple, Swage etc. And the Punching precision is within +/-0.5mm.

The use of 17 components, reasonable processes, improve efficiency and productivity, one of the processes for the flange height molding 87-95 degrees, can be arbitrarily adjusted roll set, expand the flange height selection range, more free creative manufacturing.

The power system is composed of servo motor 11KW, reducer, air-cooled, oil tank with 200L volume and solenoid valve, and the voltage is 380V and 50Hz, which can support the efficient production capacity of the MF1400.

Marks and Item Number are available to be printed on the flange side for easy assembling pieces to pieces.

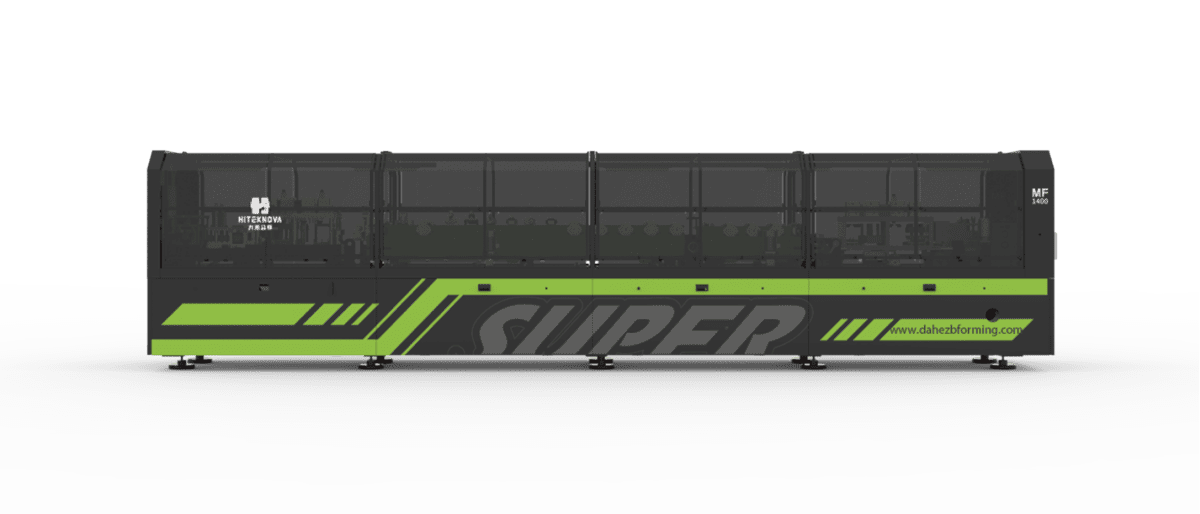

Safety Guard covers the whole machine to ensure worker’s safe.Each parts of safety guard is linked with lock.

The main body of the fuselage is gray, red rimming, and the frame is gray and black, like a meteorite in the night sky, piercing the shining new star in the sky, and the outside is matched with an integral protective cover to ensure production safety.

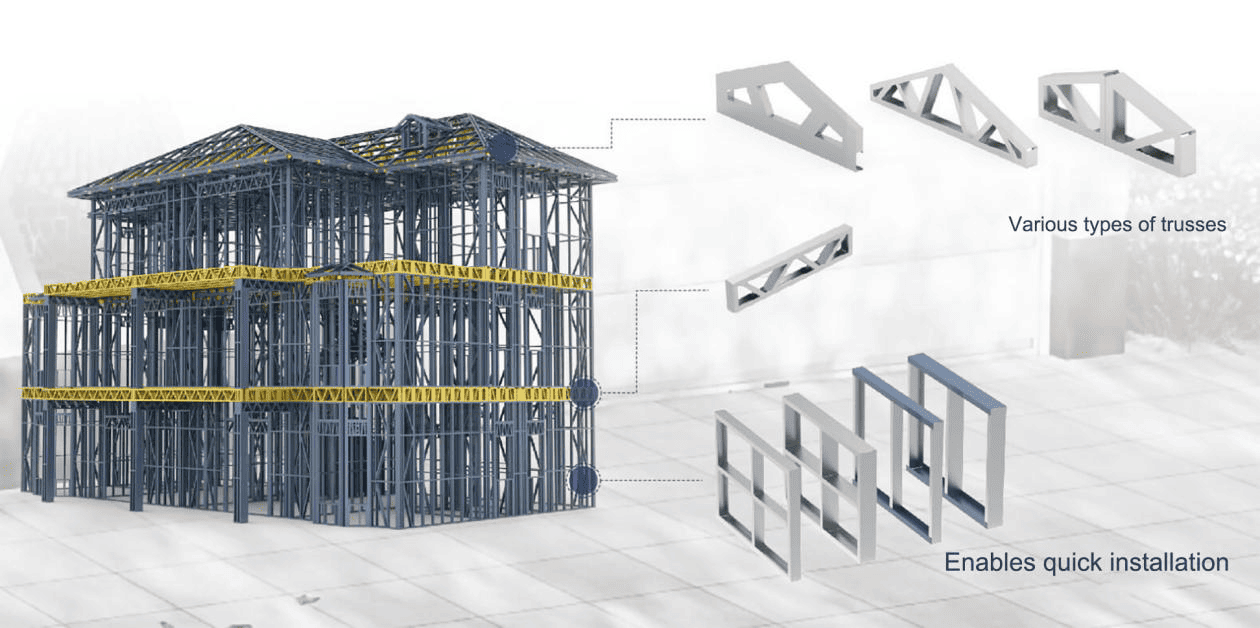

Application

- Focused on1-3 Story Residences/Villas, Partition Walls/Ceilings

- Suitable for CC & CU System